Iron Based Alloy Powder

Product Category

17-4PH Stainless Steel Powder

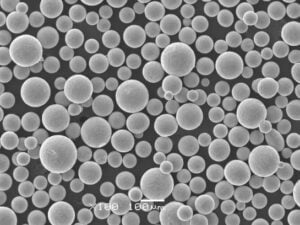

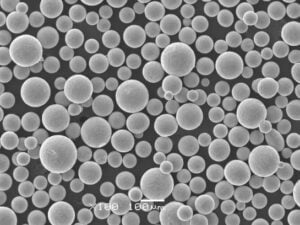

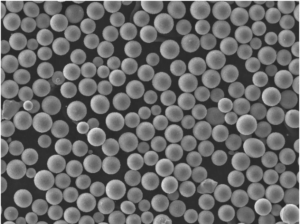

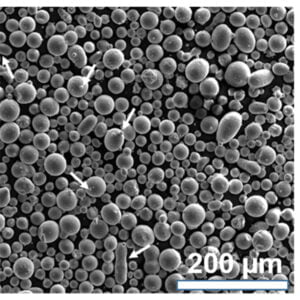

17-4PH is a precipitation hardening stainless steel powder widely used in additive manufacturing across aerospace, medical, automotive, and general engineering sectors. It offers an excellent combination of high strength, good corrosion resistance, and weldability.

300M Stainless Steel Powder

300M stainless steel powder is a specialized material used in powder metallurgy and additive manufacturing applications. This high-alloy austenitic stainless steel exhibits excellent corrosion resistance and high strength properties.

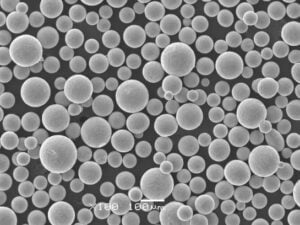

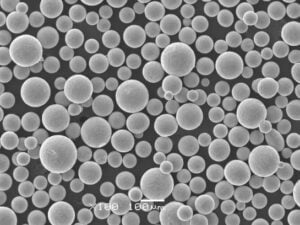

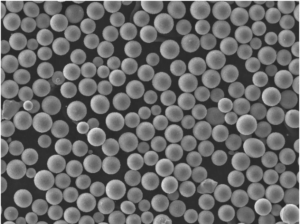

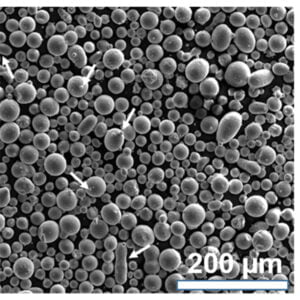

300M powder can be used to create complex metal components using advanced manufacturing techniques like selective laser sintering (SLS), direct metal laser sintering (DMLS), and binder jetting. The fine spherical powders spread easily and sinter uniformly, producing dense parts.

304l Stainless Steel Powder

304L stainless steel powder is an austenitic chromium-nickel stainless steel powder with low carbon content. It offers excellent corrosion resistance, good formability and weldability, and widely used for powder metallurgy applications. The ‘L’ denotes lower carbon compared to 304 standard grade. The low carbon minimizes carbide precipitation and maximizes corrosion resistance. Powder metallurgy 304L provides a cost-effective alternative to 316L for non-critical applications not needing molybdenum alloying.

310 Powder

310 powder is an austenitic stainless steel powder containing high levels of chromium, nickel and nitrogen for enhanced mechanical properties and corrosion resistance. It offers an excellent combination of strength, hardness, toughness and wear resistance.

316L Stainless Steel Powder

316L Stainless Steel Powder(ss316L) 316L is a stainless steel grade, which is classified according to the metallographic structure and belongs to austenitic stainless steel.

317L Powder

317L powder is an austenitic stainless steel powder containing 18% chromium, 3% molybdenum, and 0.08% carbon. It offers an excellent combination of corrosion resistance, strength, weldability and cost.

420 powder

316L is an austenitic stainless steel. The Mo content of 316L gives it excellent corrosion resistance

17-4PH is a martensitic precipitation hardening stainless steel with high strength, hardness and corrosion resistance.

420 is a martensitic stainless steel with good mechanical properties, thermal conductivity and polishing properties similar to mold steel, while maintaining good corrosion resistance.

430L Powder

430L powder is a ferritic stainless steel powder containing 17% chromium with additions of molybdenum and niobium for enhanced corrosion resistance. It provides an optimal balance of corrosion resistance, strength, weldability and cost.

A Comprehensive Guide to H13 Powder

H13 powder is a high-performance tool steel powder that exhibits exceptional strength, toughness, and heat resistance. It belongs to the family of chromium hot-work tool steels, characterized by their ability to withstand high temperatures and mechanical stresses. The powder form of H13 allows for precise and efficient manufacturing processes, making it a popular choice in various industries.

A100 steel alloy powder

A100 steel alloy powder is a specialized form of steel that consists of a precise blend of iron and other alloying elements. It is manufactured by atomization, a process that involves rapidly solidifying molten metal into fine powder particles. This fine powder exhibits excellent flowability and can be easily consolidated into various shapes using powder metallurgy techniques.

AerMet100 Stainless Steel Powder

AerMet100 stainless steel powder is an advanced high strength and corrosion resistant alloy powder designed for additive manufacturing applications. With its unique composition and properties, AerMet100 enables production of high performance parts using 3D printing processes like laser powder bed fusion and binder jetting.

This article provides a comprehensive overview of AerMet100 stainless steel powder covering its composition, properties, applications, specifications, pricing, handling, inspection methods and other technical details.

Best 17-4PH stainless steel powder for 3D Printing

17-4PH powder, also known as 17-4 Precipitation Hardening stainless steel powder, is a high-strength, corrosion-resistant material used in various industries. It belongs to the martensitic stainless steel family and offers an excellent combination of mechanical properties and corrosion resistance. The “17-4PH” designation refers to the composition of the alloy, which consists of approximately 17% chromium, 4% nickel, 4% copper, and a small amount of other elements.

Best 18Ni300 Powder for 3D printing

18Ni300 powder is a high-performance alloy composed primarily of nickel (Ni) and a balanced blend of other elements such as chromium (Cr), molybdenum (Mo), and manganese (Mn).

| Metal Powder | Size | Quantity | Price/kg |

| 18Ni300 | 15-53μm | 1KG | 72 |

| 10KG | 43 | ||

| 100KG | 35.8 |

Best Stainless Steel 316L Powder for 3D Printing

Stainless steel 316L powder is a versatile and widely used material in various industries. Its unique properties make it suitable for applications ranging from 3D printing to biomedical implants. In this article, we will explore the characteristics, uses, manufacturing process, and advantages of stainless steel 316L powder.

D2 Powder

D2 powder is a cold work tool steel powder offering an excellent combination of high hardness, wear resistance, and toughness. It is a versatile chromium-molybdenum-vanadium alloy widely used for pressing into cutting tools, dies, precision parts, and wear components across industrial sectors.

H13 Alloy Steel Powder For 3D Printing

Our nitrogen atomized H13 alloy steel powder has good hardenability, thermal strength, wear resistance and high impact toughness, thermal fatigue, widely used in the manufacture of hot work molds.Wear is one of the main failure modes of H13 steel hot-working die. Improving the surface wear resistance of H13 steel is an effective way to improve the life of die.

17-4PH Stainless Steel Powder

17-4PH is a precipitation hardening stainless steel powder widely used in additive manufacturing across aerospace, medical, automotive, and general engineering sectors. It offers an excellent combination of high strength, good corrosion resistance, and weldability.

300M Stainless Steel Powder

300M stainless steel powder is a specialized material used in powder metallurgy and additive manufacturing applications. This high-alloy austenitic stainless steel exhibits excellent corrosion resistance and high strength properties.

300M powder can be used to create complex metal components using advanced manufacturing techniques like selective laser sintering (SLS), direct metal laser sintering (DMLS), and binder jetting. The fine spherical powders spread easily and sinter uniformly, producing dense parts.

304l Stainless Steel Powder

304L stainless steel powder is an austenitic chromium-nickel stainless steel powder with low carbon content. It offers excellent corrosion resistance, good formability and weldability, and widely used for powder metallurgy applications. The ‘L’ denotes lower carbon compared to 304 standard grade. The low carbon minimizes carbide precipitation and maximizes corrosion resistance. Powder metallurgy 304L provides a cost-effective alternative to 316L for non-critical applications not needing molybdenum alloying.

310 Powder

310 powder is an austenitic stainless steel powder containing high levels of chromium, nickel and nitrogen for enhanced mechanical properties and corrosion resistance. It offers an excellent combination of strength, hardness, toughness and wear resistance.

316L Stainless Steel Powder

316L Stainless Steel Powder(ss316L) 316L is a stainless steel grade, which is classified according to the metallographic structure and belongs to austenitic stainless steel.

317L Powder

317L powder is an austenitic stainless steel powder containing 18% chromium, 3% molybdenum, and 0.08% carbon. It offers an excellent combination of corrosion resistance, strength, weldability and cost.

420 powder

316L is an austenitic stainless steel. The Mo content of 316L gives it excellent corrosion resistance

17-4PH is a martensitic precipitation hardening stainless steel with high strength, hardness and corrosion resistance.

420 is a martensitic stainless steel with good mechanical properties, thermal conductivity and polishing properties similar to mold steel, while maintaining good corrosion resistance.

430L Powder

430L powder is a ferritic stainless steel powder containing 17% chromium with additions of molybdenum and niobium for enhanced corrosion resistance. It provides an optimal balance of corrosion resistance, strength, weldability and cost.

A Comprehensive Guide to H13 Powder

H13 powder is a high-performance tool steel powder that exhibits exceptional strength, toughness, and heat resistance. It belongs to the family of chromium hot-work tool steels, characterized by their ability to withstand high temperatures and mechanical stresses. The powder form of H13 allows for precise and efficient manufacturing processes, making it a popular choice in various industries.

A100 steel alloy powder

A100 steel alloy powder is a specialized form of steel that consists of a precise blend of iron and other alloying elements. It is manufactured by atomization, a process that involves rapidly solidifying molten metal into fine powder particles. This fine powder exhibits excellent flowability and can be easily consolidated into various shapes using powder metallurgy techniques.

AerMet100 Stainless Steel Powder

AerMet100 stainless steel powder is an advanced high strength and corrosion resistant alloy powder designed for additive manufacturing applications. With its unique composition and properties, AerMet100 enables production of high performance parts using 3D printing processes like laser powder bed fusion and binder jetting.

This article provides a comprehensive overview of AerMet100 stainless steel powder covering its composition, properties, applications, specifications, pricing, handling, inspection methods and other technical details.

Best 17-4PH stainless steel powder for 3D Printing

17-4PH powder, also known as 17-4 Precipitation Hardening stainless steel powder, is a high-strength, corrosion-resistant material used in various industries. It belongs to the martensitic stainless steel family and offers an excellent combination of mechanical properties and corrosion resistance. The “17-4PH” designation refers to the composition of the alloy, which consists of approximately 17% chromium, 4% nickel, 4% copper, and a small amount of other elements.

Best 18Ni300 Powder for 3D printing

18Ni300 powder is a high-performance alloy composed primarily of nickel (Ni) and a balanced blend of other elements such as chromium (Cr), molybdenum (Mo), and manganese (Mn).

| Metal Powder | Size | Quantity | Price/kg |

| 18Ni300 | 15-53μm | 1KG | 72 |

| 10KG | 43 | ||

| 100KG | 35.8 |

Best Stainless Steel 316L Powder for 3D Printing

Stainless steel 316L powder is a versatile and widely used material in various industries. Its unique properties make it suitable for applications ranging from 3D printing to biomedical implants. In this article, we will explore the characteristics, uses, manufacturing process, and advantages of stainless steel 316L powder.

D2 Powder

D2 powder is a cold work tool steel powder offering an excellent combination of high hardness, wear resistance, and toughness. It is a versatile chromium-molybdenum-vanadium alloy widely used for pressing into cutting tools, dies, precision parts, and wear components across industrial sectors.

H13 Alloy Steel Powder For 3D Printing

Our nitrogen atomized H13 alloy steel powder has good hardenability, thermal strength, wear resistance and high impact toughness, thermal fatigue, widely used in the manufacture of hot work molds.Wear is one of the main failure modes of H13 steel hot-working die. Improving the surface wear resistance of H13 steel is an effective way to improve the life of die.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731