Orthopedic implant materials

Product Category

Best 17-4PH stainless steel powder for 3D Printing

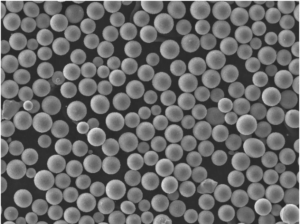

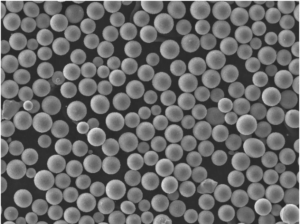

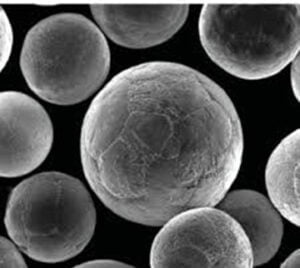

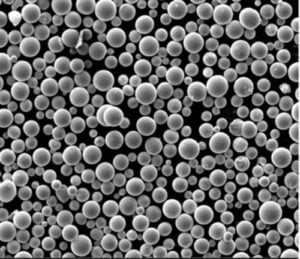

17-4PH powder, also known as 17-4 Precipitation Hardening stainless steel powder, is a high-strength, corrosion-resistant material used in various industries. It belongs to the martensitic stainless steel family and offers an excellent combination of mechanical properties and corrosion resistance. The “17-4PH” designation refers to the composition of the alloy, which consists of approximately 17% chromium, 4% nickel, 4% copper, and a small amount of other elements.

CoCrMoW Powder

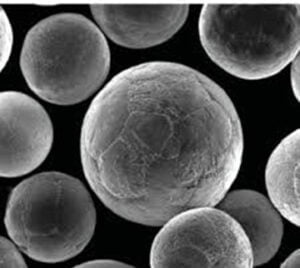

CoCrMoW powder is a cobalt-chromium-molybdenum-tungsten alloy powder used primarily for manufacturing of orthopedic joint implants. The addition of tungsten further enhances the strength, wear resistance and hardness compared to CoCrMo alloys.

CoCrW Powder for metal 3D printing

CoCrW is one of the the stellite alloys, which can resist various types of wear, corrosion and oxidation at high temperature. According to the compositions of alloys, they can be made into welding wire, powder to be used for hard surface surfacing, thermal spraying, spray welding. They can also be made into castings, forgings and powder metallurgy parts.

Stainless Steel 316L Powder for Metal 3D Printing

Stainless steel 316L powder is a type of stainless steel powder that contains molybdenum and has low carbon content. It is an austenitic chromium-nickel stainless steel that exhibits high strength and excellent corrosion resistance properties. 316L powder is widely used for 3D printing or additive manufacturing applications across industries such as aerospace, medical, automotive, and general manufacturing.

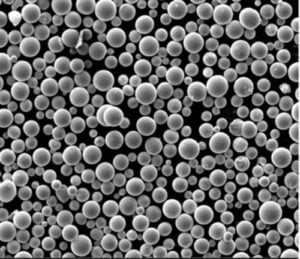

Ti6Al4V Powder Titanium Based Metal Powder for Additive Manufacturing

Ti6Al4V powder for 3D printing price list :

| Metal Powder | Size | Quantity | Price/kg | Size | Quantity | Price/kg |

| TiAl6V4 gr.23 | 20-63μm | 1KG | 138 | 0-45μm | 1KG | 144 |

| 10KG | 109 | 10KG | 124 | |||

| 100KG | 105 | 100KG | 117 |

Best 17-4PH stainless steel powder for 3D Printing

17-4PH powder, also known as 17-4 Precipitation Hardening stainless steel powder, is a high-strength, corrosion-resistant material used in various industries. It belongs to the martensitic stainless steel family and offers an excellent combination of mechanical properties and corrosion resistance. The “17-4PH” designation refers to the composition of the alloy, which consists of approximately 17% chromium, 4% nickel, 4% copper, and a small amount of other elements.

CoCrMoW Powder

CoCrMoW powder is a cobalt-chromium-molybdenum-tungsten alloy powder used primarily for manufacturing of orthopedic joint implants. The addition of tungsten further enhances the strength, wear resistance and hardness compared to CoCrMo alloys.

CoCrW Powder for metal 3D printing

CoCrW is one of the the stellite alloys, which can resist various types of wear, corrosion and oxidation at high temperature. According to the compositions of alloys, they can be made into welding wire, powder to be used for hard surface surfacing, thermal spraying, spray welding. They can also be made into castings, forgings and powder metallurgy parts.

Stainless Steel 316L Powder for Metal 3D Printing

Stainless steel 316L powder is a type of stainless steel powder that contains molybdenum and has low carbon content. It is an austenitic chromium-nickel stainless steel that exhibits high strength and excellent corrosion resistance properties. 316L powder is widely used for 3D printing or additive manufacturing applications across industries such as aerospace, medical, automotive, and general manufacturing.

Ti6Al4V Powder Titanium Based Metal Powder for Additive Manufacturing

Ti6Al4V powder for 3D printing price list :

| Metal Powder | Size | Quantity | Price/kg | Size | Quantity | Price/kg |

| TiAl6V4 gr.23 | 20-63μm | 1KG | 138 | 0-45μm | 1KG | 144 |

| 10KG | 109 | 10KG | 124 | |||

| 100KG | 105 | 100KG | 117 |

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731