Al 6061 powder for additive manufacturing (AM)

Al 6061 powder is a versatile aluminum material composed of various elements to enhance its properties, such as strength, corrosion resistance, and machinability. It is widely used in different industries for its excellent characteristics.

Low MOQ

Provide low minimum order quantity to meet different needs.

OEM & ODM

Provide customized products and design services to meet unique customer needs.

Adequate Stock

Ensure fast order processing and provide reliable and efficient service.

Customer Satisfaction

Provide high quality products with customer satisfaction at the core.

share this product

Table of Contents

Overview of Al 6061 Powder

Al 6061 is one of the most versatile heat treatable aluminum alloys. Magnesium and silicon additions allow it to be strengthened through precipitation hardening. The alloy has become immensely popular due to its excellent corrosion resistance, machinability, weldability and medium to high strength.

Key characteristics of Al 6061 powder include:

- Medium to high strength with excellent ductility and toughness

- Excellent corrosion resistance and finishability

- Very good weldability and machinability

- High thermal and electrical conductivity

- Low density

- Available in a wide range of powder sizes and shapes

Al 6061 powder is used widely for aerospace, marine, automotive, construction and general engineering applications needing lightweight and good mechanical properties.

Chemical Composition of Al 6061 Powder

The typical chemical composition of Al 6061 powder is:

| Element | Weight % |

|---|---|

| Aluminum (Al) | Balance |

| Silicon (Si) | 0.4-0.8% |

| Iron (Fe) | 0-0.7% |

| Copper (Cu) | 0.15-0.4% |

| Manganese (Mn) | 0-0.15% |

| Magnesium (Mg) | 0.8-1.2% |

| Chromium (Cr) | 0.04-0.35% |

| Zinc (Zn) | 0-0.25% |

| Titanium (Ti) | 0-0.15% |

Magnesium and silicon are the key alloying elements. Trace amounts of iron, copper, manganese and chromium also have minor effects on the alloy properties.

Properties of Al 6061 Powder

Key properties of Al 6061 powder include:

| Property | Value |

|---|---|

| Density | 2.7 g/cm3 |

| Melting Point | 582-652°C |

| Thermal Conductivity | 167 W/mK |

| Electrical Conductivity | 43-45% IACS |

| Young’s Modulus | 68-72 GPa |

| Poisson’s Ratio | 0.33 |

| Tensile Strength | 124-290 MPa |

| Yield Strength | 55-250 MPa |

| Elongation | 10-25% |

| Hardness | 40-95 Brinell |

Al 6061 offers medium to high strength that can be further enhanced through heat treatment. It possesses excellent corrosion resistance and finishability.

Production Method for Al 6061 Powder

Commercial production methods for Al 6061 powder include:

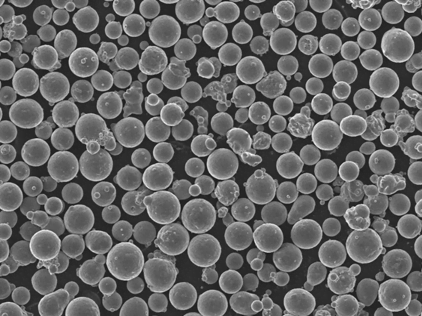

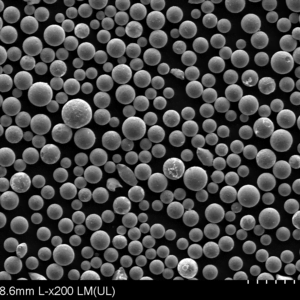

- Gas Atomization – High pressure inert gas disintegrates molten alloy stream into fine spherical powder with controlled size distribution.

- Water Atomization – High velocity water jet impacts and disintegrates molten metal to produce fine irregular powder particles.

- Mechanical Alloying – Ball milling a blend of aluminum and alloying element powders followed by compaction and sintering.

Gas atomization provides superior control over the powder characteristics.

Applications of Al 6061 Powder

Typical applications of Al 6061 powder include:

- Additive Manufacturing – Used in selective laser melting, electron beam melting and binder jetting to produce complex components.

- Metal Injection Molding – To manufacture small intricate parts with tight tolerances and excellent properties.

- Powder Metallurgy – Press and sinter process to create high performance automotive and mechanical parts.

- Thermal Spraying – Wire arc spraying to deposit protective Al 6061 coatings offering wear and corrosion resistance.

- Welding Filler – Used as filler wire to provide weld strength similar to base metal.

- Pigments – Added to paints and polymers to provide luster and corrosion protection.

Specifications of Al 6061 Powder

Al 6061 powder is available under different size ranges, shapes, grades and purity levels:

- Particle Size: From 10-150 microns for AM methods, up to 300 microns for thermal spray processes.

- Morphology: Spherical, granular, dendritic and irregular shaped particles. Smooth powder flows better.

- Purity: From commercial to high purity (99.9%) tailored to meet requirements.

- Grades: Conforming to ASTM B221, EN 573, and ISO 209 specifications. Custom grades offered.

- Flowability: Powder can be customized for specific flow rates based on application.

Global Suppliers of Al 6061 Powder

Some of the major global suppliers are:

- Valimet Inc. (USA)

- Makin Metal Powders (UK)

- Metal Powder Company (USA)

- CNPC Powder Group (China)

- SCM Metal Products (USA)

- Shanghai Chaowei Nanotechnology (China)

- Titanium Powder (Russia)

These companies produce Al 6061 powder suitable for AM, thermal spray, aerospace, automotive and other demanding applications using various methods.

Al 6061 Powder Pricing

Pricing of Al 6061 powder depends on several factors:

- Purity levels

- Particle characteristics

- Powder production method

- Order volume

- Supplier and geographical location

| Grade | Price Range |

|---|---|

| Commercial | $5-15 per kg |

| High purity | $15-30 per kg |

| Ultrafine | $30-60 per kg |

| Special grade | $60-120 per kg |

Spherical, controlled particle size and high purity powders command much higher pricing over regular commercial grades of Al 6061 powder.

Storage and Handling of Al 6061 Powder

Al 6061 powder should be properly handled and stored to prevent:

- Oxidation and reaction with moisture

- Dust explosion hazards from fine powder

- Inhalation related health problems

- Safety practices from supplier SDS should be followed

Inert gas storage, adequate ventilation, grounding, and PPE is recommended when handling the powder.

Testing and Characterization Methods

Key test methods used for Al 6061 powder include:

- Chemical analysis using OES or XRF for composition

- Particle size distribution as per ASTM B822 standard

- Morphology analysis through SEM

- Powder flow rate measured by Hall flow funnel

- Density determination by helium pycnometry

- Impurity testing by ICP-MS

- Microstructure examination by X-ray diffraction

These tests ensure batch consistency and compliance with application requirements.

Comparison Between Al 6061 and Al 7075 Powders

Al 6061 and Al 7075 are two aluminum alloy powders compared:

| Parameter | Al 6061 | Al 7075 |

|---|---|---|

| Alloy type | Heat treatable | Heat treatable |

| Mg content | 0.8-1.2% | 2.1-2.9% |

| Strength | Medium | Very high |

| Machinability | Excellent | Poor |

| Weldability | Excellent | Poor |

| Corrosion resistance | Excellent | Good |

| Cost | Lower | Higher |

Al 6061 offers better corrosion resistance and machinability while Al 7075 provides much greater strength after heat treatment.

Al 6061 Powder FAQs

Q: How is Al 6061 powder produced?

A: Al 6061 powder is commercially produced using gas atomization, water atomization, mechanical alloying, and electrolysis techniques. Gas atomization offers optimal control of powder characteristics.

Q: What are the main applications of Al 6061 powder?

A: Key applications for Al 6061 powder include additive manufacturing, thermal spray coatings, powder metallurgy parts, metal injection molding, pigments, and welding filler wire requiring medium strength and excellent corrosion resistance.

Q: What is the recommended Al 6061 powder size for binder jetting?

A: For binder jetting process, the typical Al 6061 powder size range is 20-45 microns with spherical morphology to enable good powder bed density and binder infiltration.

Q: Does Al 6061 powder require any special handling precautions?

A: Yes, it is recommended to handle aluminum alloy powders carefully under inert atmosphere with proper grounding, ventilation and PPE to prevent fire or explosion hazards.

Q: Where can I buy Al 6061 powder suitable for aerospace applications?

A: High purity gas atomized Al 6061 powder meeting aerospace standards can be purchased from leading manufacturers like Valimet, Makin Metal Powders, and AMETEK.

Get Latest Price

About Met3DP

Product Category

HOT SALE

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731