Best 18Ni300 Powder for 3D printing

18Ni300 powder is a high-performance alloy composed primarily of nickel (Ni) and a balanced blend of other elements such as chromium (Cr), molybdenum (Mo), and manganese (Mn).

| Metal Powder | Size | Quantity | Price/kg |

| 18Ni300 | 15-53μm | 1KG | 72 |

| 10KG | 43 | ||

| 100KG | 35.8 |

Low MOQ

Provide low minimum order quantity to meet different needs.

OEM & ODM

Provide customized products and design services to meet unique customer needs.

Adequate Stock

Ensure fast order processing and provide reliable and efficient service.

Customer Satisfaction

Provide high quality products with customer satisfaction at the core.

share this product

Table of Contents

Properties and Characteristics of 18Ni300 Powder

18Ni300 powder boasts a unique combination of properties that make it a highly sought-after material for 3D printing applications. Here are some of its key characteristics:

| Property | Description |

|---|---|

| High Strength and Toughness | Even after 3D printing, 18Ni300 parts exhibit exceptional strength and toughness, making them ideal for demanding applications. Imagine a 3D-printed gear that can withstand incredible pressure without breaking – that’s the power of 18Ni300. |

| Excellent Wear Resistance | This material stands up to wear and tear remarkably well. Think of a 3D-printed mold that retains its shape and function even after countless uses. |

| Low-Carbon Content | The low carbon content minimizes the risk of cracking during the 3D printing process, ensuring smooth and reliable production. |

| Good Weldability | 18Ni300 parts can be readily welded, allowing for the creation of complex structures or the joining of 3D-printed components with traditional manufacturing techniques. |

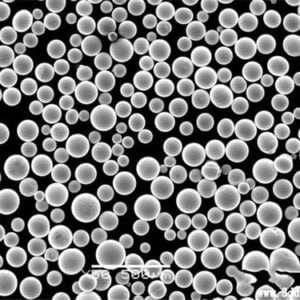

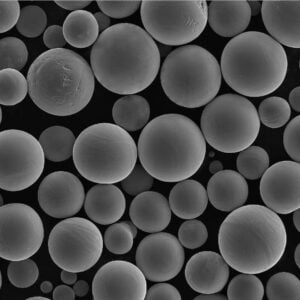

| High Dimensional Accuracy | The spherical shape and consistent particle size of 18Ni300 powder contribute to excellent dimensional accuracy in the final 3D-printed parts. |

Exploring 18Ni300 Powder Applications

The exceptional properties of 18Ni300 powder translate into a wide range of potential applications across various industries. Here are some exciting areas where this material is making its mark:

| Industry | Application Examples |

|---|---|

| Aerospace | High-strength components for aircraft landing gear, rocket engine parts, and other critical structures. |

| Oil & Gas | Wear-resistant parts for downhole tools, valves, and other equipment exposed to harsh environments. |

| Automotive | High-performance gears, shafts, and other components for demanding applications. |

| Medical | Biocompatible implants and surgical instruments requiring exceptional strength and durability. |

| Defense | Armor components, weapon parts, and other applications where lightweight yet robust materials are essential. |

18Ni300 Powder Price:

| Metal Powder | Size | Quantity | Price/kg |

| 18Ni300 | 15-53μm | 1KG | 72 |

| 10KG | 43 | ||

| 100KG | 35.8 |

Specifying Your Needs: Specifications, Sizes, and Grades

When selecting 18Ni300 powder for your 3D printing project, it’s crucial to consider the specific requirements of your application. Here’s a breakdown of some key specifications to keep in mind:

| Specification | Description |

|---|---|

| Particle Size | The size of the powder particles significantly impacts the final properties and printability of the 3D-printed part. Finer powders generally offer better surface finish and detail but may require specialized printing equipment. |

| Flowability | The powder’s ability to flow freely is essential for even distribution during the 3D printing process. Good flowability ensures consistent material deposition and minimizes printing defects. |

| Apparent Density | This refers to the weight of powder per unit volume. It’s a crucial factor for determining the amount of material needed for your print and optimizing printing parameters. |

| Grade | Different grades of 18Ni300 powder may offer variations in composition or properties to cater to specific application needs. For instance, some grades might prioritize higher strength, while others focus on improved machinability. |

Understanding the Options: Available Sizes and Standards

18Ni300 powder is typically available in a range of particle sizes to suit various 3D printing technologies. Some common size ranges include:

- 15-45 micrometers (µm)

- 45-75 µm

- 75-100 µm

The choice of particle size depends on the specific 3D printing process and the desired part properties. For example, laser beam melting (LBM) often utilizes finer powders (15-45 µm) for high-resolution printing, while electron beam melting (EBM) can handle slightly larger particles (45-75 µm).

Several industry standards govern the quality and specifications of metal powders for additive manufacturing, including 18Ni300 powder. Here are some relevant standards to be aware of:

- ASTM International (ASTM) F3049 – Standard Specification for Metal Powders Used in Additive Manufacturing Processes

- Aerospace Material Specifications (AMS) 5649 – Additive Manufacturing Powder, Maraging Steel, 18Ni-3Co-3Mo-0.5Ti

Frequently Asked Questions (FAQ) About 18Ni300 Powder

Q: What are the advantages of using 18Ni300 powder for 3D printing?

A: 18Ni300 powder offers a compelling combination of high strength, toughness, excellent wear resistance, and good weldability. It also boasts low-carbon content for minimized cracking risk and good dimensional accuracy in printed parts.

Q: What are some limitations of 18Ni300 powder?

A: Compared to some other metal powders, 18Ni300 may require a post-printing heat treatment process to achieve its full strength and toughness potential. Additionally, the material can be more expensive than some commonly used 3D printing materials.

Q: Is 18Ni300 powder safe to handle?

A: Metal powders, including 18Ni300, can pose health risks if inhaled. It’s crucial to follow proper safety protocols when handling these materials, including using appropriate personal protective equipment (PPE) and working in a well-ventilated environment.

Q: What are the future prospects for 18Ni300 powder in 3D printing?

A: With ongoing research and development, 18Ni300 powder is expected to play an increasingly significant role in 3D printing. Advancements in powder production technologies and 3D printing processes could further enhance the printability and properties of this versatile material, unlocking new possibilities for high-performance metal additive manufacturing.

By understanding the composition, properties, applications, and supplier landscape of 18Ni300 powder, you’re well-equipped to leverage this powerful material for your 3D printing projects. Remember to carefully consider your specific needs and consult with reputable suppliers to ensure you select the optimal 18Ni300 powder for your application.

Get Latest Price

About Met3DP

Product Category

HOT SALE

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731