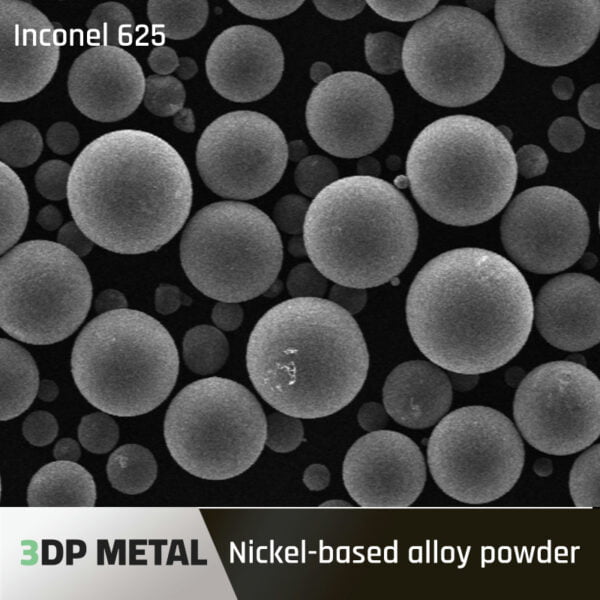

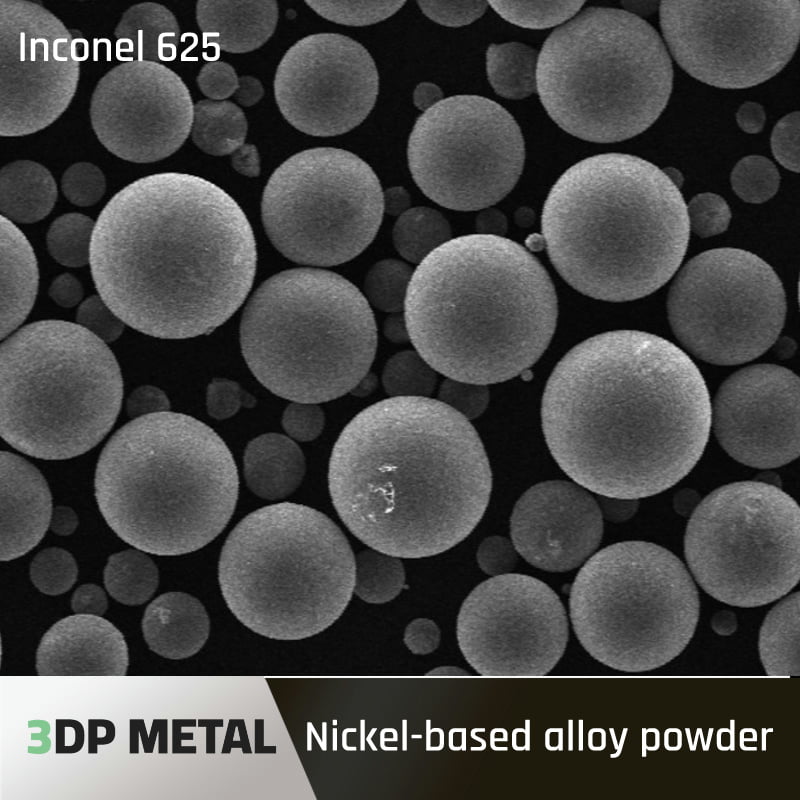

Best Inconel 625 Powder for metal 3D printing

Inconel 625 powder price list:

| Metal Powder | Size | Quantity | Price/kg | Size | Quantity | Price/kg |

| Inconel 625 | 0-20μm | 1KG | $59 | 20-63μm | 1KG | $98.30 |

| 10KG | $39 | 10KG | $69.10 | |||

| 100KG | $34 | 100KG | $64.50 |

Low MOQ

Provide low minimum order quantity to meet different needs.

OEM & ODM

Provide customized products and design services to meet unique customer needs.

Adequate Stock

Ensure fast order processing and provide reliable and efficient service.

Customer Satisfaction

Provide high quality products with customer satisfaction at the core.

share this product

Table of Contents

Overview

Inconel 625 powder is a nickel-chromium-molybdenum alloy powder that offers high strength and outstanding corrosion resistance. It has excellent fatigue strength and stress corrosion cracking resistance. The key features of nickel alloy 625 powder include:

- High strength and toughness from -425°F (-254°C) to 1800°F (982°C)

- Outstanding corrosion resistance in various corrosive environments

- Excellent oxidation resistance up to 2000°F (1093°C)

- Resists pitting and crevice corrosion

- Excellent fatigue strength and thermal fatigue resistance

- Resists stress corrosion cracking

- Easy to weld and fabricate

- Available in various particle sizes for additive manufacturing

Some of the key composition details, properties, applications, and specifications of nickel alloy 625 powder are summarized in the tables below:

Inconel 625 Powder Composition

| Element | Weight % |

|---|---|

| Nickel (Ni) | 58.0 min |

| Chromium (Cr) | 20.0-23.0 |

| Molybdenum (Mo) | 8.0-10.0 |

| Iron (Fe) | 5.0 max |

| Niobium (Nb) + Tantalum (Ta) | 3.15-4.15 |

| Carbon (C) | 0.05 max |

| Manganese (Mn) | 0.50 max |

| Silicon (Si) | 0.50 max |

| Phosphorus (P) | 0.015 max |

| Sulfur (S) | 0.015 max |

| Boron (B) | 0.006 max |

| Copper (Cu) | 0.5 max |

| Cobalt (Co) | 1.0 max |

| Aluminum (Al) | 0.4 max |

| Titanium (Ti) | 0.4 max |

| Zirconium (Zr) | 0.05 max |

The nickel content gives nickel alloy 625 excellent corrosion resistance. Chromium provides good oxidation and corrosion resistance. Molybdenum further enhances corrosion resistance, especially in reducing environments. Niobium prevents precipitation of deleterious intermetallic phases to maintain high strength and toughness. Iron enhances high temperature strength. Controlled amounts of other alloying elements fine tune the properties.

Inconel 625 Powder Properties

| Property | Value |

|---|---|

| Density | 8.44 g/cm3 |

| Melting Point | 2335-2460°F (1276-1349°C) |

| Thermal Conductivity | 9.8 W/m-K |

| Electrical Resistivity | 117 μΩ-cm |

| Modulus of Elasticity | 205 GPa |

| Poisson’s Ratio | 0.278 |

| Tensile Strength | 125-160 ksi (862-1103 MPa) |

| Yield Strength (0.2% offset) | 80-100 ksi (552-690 MPa) |

| Elongation | 35-40% |

| Hardness | 25-35 HRC |

| Relative Magnetic Permeability | 1.002 max |

The combination of properties like high strength, good fabricability and weldability, excellent corrosion resistance, and good fatigue strength make nickel alloy 625 suitable for a wide range of applications.

Inconel 625 Powder Applications

Some of the common applications of nickel alloy 625 powder include:

| Industry | Applications |

|---|---|

| Aerospace | Engine discs, cases, exhaust systems, fasteners |

| Oil & Gas | Wellhead equipment, offshore rigs, valves, fluid handling parts |

| Chemical & Petrochemical | Heat exchangers, piping, valves, reactors |

| Pollution Control | Scrubbers, flue gas stacks, heat exchangers |

| Marine | Propeller shafts, equipment for desalination plants |

| Food processing | Highly corrosion resistant equipment |

| Pharmaceutical | Reactors, condensers, heat exchangers |

| Power Generation | Heat exchanger tubing |

| Additive Manufacturing | High temperature, corrosion resistant parts |

The good weldability and fabricability allows it to be made into various components using standard metal manufacturing techniques. The corrosion resistance allows it to withstand exposure to many organic and inorganic chemicals across a wide temperature range. Hence nickel alloy 625 finds usage in various critical applications.

Advantages:

- Excellent corrosion resistance

- High temperature strength

- Good fabricability and weldability

- Resists pitting and crevice corrosion

- Oxidation and fatigue resistance

Disadvantages:

- More expensive than stainless steels

- Lower thermal conductivity than copper alloys

- Not as strong as ferritic steels

Inconel 625 Powder Specifications

Nickel alloy 625 powder is available in various standard specifications:

| Specification | Description |

|---|---|

| AMS 5666 | Nickel Alloy, Corrosion and Heat-Resistant, Bars, Forgings, and Rings 62Ni – 22Cr – 9Mo – 3.8Nb |

| AMS 5837 | Wire, Nickel Alloy 625 |

| ASME SB-443 | Seamless and Welded Nickel Alloy 625 Pipes and Tubes |

| ASTM B348 | Titanium and Titanium Alloy Bars and Billets |

| AMS 2241 | Nickel Alloy, Corrosion Resistant 62Ni – 21.5Cr – 9Mo – 3.65 Nb Alloy (UNS N06625) Plate, Sheet, and Strip |

| ISO 10271 | Corrosion-resistant nickel-chromium-molybdenum alloy (UNS N06625) plate, sheet and strip |

These specifications define the required chemical composition limits, mechanical properties, grain size control, testing methods, lot traceability, etc. for quality assurance and reliable performance.

Inconel 625 Powder Suppliers and Pricing

Some of leading global suppliers of nickel alloy 625 powder include:

| Supplier | Particle Sizes | Price Range |

|---|---|---|

| Sandvik Osprey | 15-150 μm | $50-60 per kg |

| Carpenter Additive | 15-45 μm | $75-100 per kg |

| Praxair Surface Technologies | 10-150 μm | $55-90 per kg |

| Hoganas | 45-150 μm | $45-75 per kg |

| LPW Technology | 20-63 μm | $60-120 per kg |

| Erasteel | 75-150 μm | $40-65 per kg |

Nickel alloy 625 powder can be purchased directly from these metal powder producers. Prices vary based on order quantity, shipping, and other value added services. Small quantity samples for R&D purposes are also available.

Met3DP inconel 625 powder price list:

| Metal Powder | Size | Quantity | Price/kg | Size | Quantity | Price/kg |

| Inconel 625 | 0-20μm | 1KG | $59 | 20-63μm | 1KG | $98.30 |

| 10KG | $39 | 10KG | $69.10 | |||

| 100KG | $34 | 100KG | $64.50 |

Inconel 625 Powder Comparison with Other Alloys

Versus Stainless Steel 316L powder

| Parameter | Nickel Alloy 625 | Stainless Steel 316L |

|---|---|---|

| Density | Higher | 7.9 g/cm3 |

| Tensile Strength | Comparable | 515 MPa |

| Temperature Resistance | 2X higher | 1300°F |

| Corrosion Resistance | 5X better | Average |

| Cost | 4X higher | Lower |

Versus Inconel 718 powder

| Parameter | Nickel Alloy 625 | Inconel 718 |

|---|---|---|

| Machinability | Easier | Difficult |

| Corrosion Resistance | Higher | Moderate |

| Cost | Comparable | Similar |

| Cold Workability | Better | Average |

Versus Hastelloy C276 powder

| Parameter | Nickel Alloy 625 | Hastelloy C276 |

|---|---|---|

| Density | Same | 8.9 g/cm3 |

| Thermal Expansion | Lower | Comparable |

| Heat Treatment | Not needed | Sometimes needed |

| Cost | Lower | Higher |

| Fabrication | Easier | More Difficult |

Inconel 625 Powder FAQs

Q. What is nickel alloy 625?

A. Nickel alloy 625 is a nickel-chromium-molybdenum alloy with additions like niobium that offer an excellent combination of high strength and outstanding corrosion resistance up to 1900°F (1040°C).

Q. Why choose nickel alloy 625 powder?

A. The key advantages are superior corrosion resistance across many environments, good mechanical properties at high temps, excellent fatigue strength, and suitability for additive manufacturing of complex parts.

Q. What is nickel alloy 625 powder used for?

A. Nickel alloy 625 powder has applications in aerospace, chemical processing, petrochemical, marine, pollution control and power industries where strength, corrosion resistance, or high temp performance are needed.

Q. Does nickel alloy 625 require heat treatment?

A. No. Nickel Alloy 625, often simply referred to as Alloy 625 or Inconel 625, is unique in that it doesn’t usually require heat treatment.

Get Latest Price

About Met3DP

Product Category

HOT SALE

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731