TC11 Powder : A Comprehensive Guide

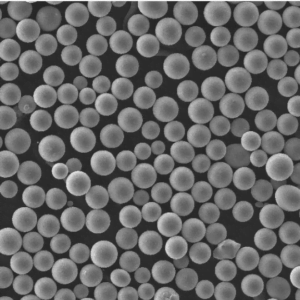

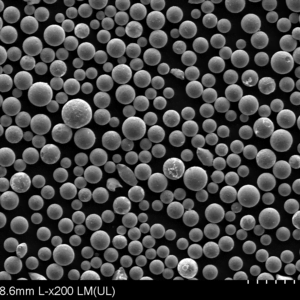

TC11 powder, also known as Titanium Carbide 11, is a cutting-edge material with remarkable properties. It is composed of titanium and carbon atoms, resulting in a high-strength, lightweight powder that exhibits excellent wear resistance and thermal stability.

Low MOQ

Provide low minimum order quantity to meet different needs.

OEM & ODM

Provide customized products and design services to meet unique customer needs.

Adequate Stock

Ensure fast order processing and provide reliable and efficient service.

Customer Satisfaction

Provide high quality products with customer satisfaction at the core.

share this product

Table of Contents

1. What Is TC11 Powder?

TC11 powder, also known as Titanium Carbide 11, is a cutting-edge material with remarkable properties. It is composed of titanium and carbon atoms, resulting in a high-strength, lightweight powder that exhibits excellent wear resistance and thermal stability.

2. Properties Of TC11 Powder

TC11 powder possesses several noteworthy properties that make it an ideal choice for various applications. Some key properties of TC11 powder include:

- High hardness and wear resistance

- Excellent thermal stability

- Low density

- Good electrical conductivity

- Chemical inertness

3. Advantages And Benefits Of TC11 Powder

The utilization of TC11 powder brings forth numerous advantages and benefits. These include:

- Enhanced mechanical properties

- Extended lifespan of components

- Reduced weight and improved fuel efficiency

- Increased resistance to high temperatures

- Enhanced electrical conductivity

- Superior corrosion resistance

4. Applications Of TC11 Powder

The versatility of TC11 powder allows for its utilization in a wide range of industries. Some notable applications of TC11 powder are:

5. The Role Of TC11 Powder In Aerospace Industry

In the aerospace industry, TC11 powder finds extensive use in manufacturing lightweight components for aircraft and spacecraft. Its high strength, low density, and exceptional thermal stability make it an excellent choice for producing turbine blades, engine components, and structural parts.

6. TC11 Powder In Automotive Manufacturing

The automotive industry can benefit greatly from TC11 powder. By incorporating TC11 powder in the manufacturing process, automakers can create lighter and more fuel-efficient vehicles. TC11 powder is used in producing engine parts, exhaust systems, and suspension components.

7. TC11 Powder In Medical Applications

TC11 powder has found its way into the medical field due to its biocompatibility and excellent wear resistance. It is used in orthopedic implants, dental prosthetics, and surgical instruments. The use of TC11 powder ensures long-lasting and reliable medical devices.

8. TC11 Powder In Electronics And Gadgets

The electrical conductivity and thermal stability of TC11 powder make it highly suitable for electronics and gadget manufacturing. It is used in the production of circuit boards, heat sinks, and various electronic components.

9. TC11 Powder In Sports And Recreation

In sports and recreation, TC11 powder plays a significant role. It is used in the manufacturing of sports equipment such as golf clubs, tennis rackets, and bicycle frames. The lightweight and durable nature of TC11 powder make it an excellent choice for performance-driven applications.

10. TC11 Powder In Defense And Military

TC11 powder has garnered interest in the defense and military sectors. It is used in the production of armor plates, ballistic vests, and protective gear. TC11 powder provides enhanced protection while ensuring lightweight and agile equipment.

11. How To Choose The Right TC11 Powder Supplier

When selecting a TC11 powder supplier, it is crucial to consider certain factors. Look for a supplier that offers high-quality TC11 powder, adheres to industry standards, provides technical support, and has a reliable track record.

12. Safety Considerations And Handling Of TC11 Powder

While TC11 powder offers numerous benefits, proper safety precautions must be followed during handling and processing. It is important to wear appropriate protective gear, ensure adequate ventilation, and follow the recommended guidelines provided by the manufacturer.

13. Future Prospects And Development Of TC11 Powder

As technology advances, the development of TC11 powder continues to progress. Researchers are exploring new manufacturing techniques and optimizing its properties for even broader applications. The future of TC11 powder holds immense potential in revolutionizing various industries.

Conclusion

TC11 powder has emerged as a remarkable material with outstanding properties and limitless potential. Its unique combination of strength, lightness, and versatility has made it a valuable asset in industries such as aerospace, automotive, medical, electronics, sports, and defense. As TC11 powder continues to evolve, its impact on innovation and technological advancements is set to increase.

Frequently Asked Questions (FAQs)

- What are the main characteristics of TC11 powder?TC11 powder possesses high hardness, wear resistance, low density, good electrical conductivity, and chemical inertness.

- Is TC11 powder suitable for high-temperature applications?Yes, TC11 powder exhibits excellent thermal stability, making it suitable for high-temperature environments.

- Can TC11 powder be used in additive manufacturing?Absolutely, TC11 powder can be used in additive manufacturing processes like 3D printing to create intricate and customized components.

- Are there any health risks associated with TC11 powder?When handled and processed following proper safety guidelines, TC11 powder poses minimal health risks. It is important to take necessary precautions during handling and use.

- Where can I purchase TC11 powder?You can find TC11 powder from reputable suppliers and distributors. Visit our website here to access reliable sources for TC11 powder.

Get Latest Price

About Met3DP

Product Category

HOT SALE

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731