Titanium alloy 3D printed metal powder

Table of Contents

Imagine a metal that’s incredibly strong, yet remarkably lightweight. A material that resists corrosion like a champion and integrates seamlessly with the human body. That’s the magic of titanium alloys, and when combined with the transformative power of 3D printing, it opens doors to a world of groundbreaking possibilities. Buckle up, because we’re diving deep into the fascinating realm of titanium alloy 3D printed metal powder!

Pure Titanium vs. Titanium Alloys

Before we delve into the world of 3D printed powders, let’s establish a foundation. Titanium, in its pure form, boasts an impressive resume. It’s incredibly strong for its weight, a characteristic that has endeared it to the aerospace industry. Think about the sleek, silver giants soaring through the sky – titanium is likely a key player in their construction. But here’s the catch: while pure titanium shines in biocompatibility, meaning it plays nicely with the human body, its overall strength can be a bit lacking for some applications.

Enter the world of titanium alloys. By strategically blending titanium with other elements like aluminum or vanadium, we unlock a whole new spectrum of properties. Imagine adding spices to a dish – each element acts like a unique seasoning, enhancing specific characteristics. These alloys offer a significant boost in strength and corrosion resistance, making them ideal for demanding environments like aerospace components, chemical processing equipment, and even high-performance sporting goods.

Here’s a quick comparison to illustrate the point:

| Feature | Pure Titanium | Titanium Alloy (e.g., Ti-6Al-4V) |

|---|---|---|

| Biocompatibility | High | Moderate |

| Strength | Moderate | High |

| Corrosion Resistance | High | High (often even better) |

So, when do you choose pure titanium versus an alloy? If biocompatibility is paramount, pure titanium reigns supreme. Think about medical implants like hip replacements or dental screws – these components need to integrate seamlessly with the body, and pure titanium fits the bill perfectly. However, if strength and corrosion resistance are top priorities, a titanium alloy like Ti-6Al-4V (a popular choice containing aluminum and vanadium) might be the better option.

Titanium alloy 3D printed metal powder

Now that we understand the power of titanium alloys, let’s explore how 3D printing takes things to a whole new level. Traditional manufacturing methods often involve machining solid blocks of metal, a process that can be wasteful and limiting in terms of design complexity.

3D printing, also known as additive manufacturing, flips the script. Here, the titanium alloy powder takes center stage. Imagine tiny grains of metal, each packed with potential. The 3D printer, acting like a skilled sculptor, meticulously lays down these particles layer by layer, building the desired object with incredible precision. Think intricate lattice structures for weight reduction, complex geometries previously impossible to achieve, and even internal channels for fluid flow – the design possibilities are truly mind-boggling.

Here’s a glimpse into the advantages of 3D printing titanium alloys:

- Design Freedom: Unleash your creativity! 3D printing allows for intricate designs that would be impossible with traditional methods.

- Lightweighting: By incorporating internal structures like lattices, designers can significantly reduce weight while maintaining strength – a game-changer for aerospace and other weight-sensitive applications.

- Reduced Waste: 3D printing uses only the necessary material, minimizing waste compared to traditional methods that involve significant material removal.

- Faster Prototyping: The ability to quickly iterate and create prototypes allows for faster development cycles and product innovation.

Of course, no technology is perfect. 3D printing titanium alloys can be a bit more expensive compared to some traditional methods, and the build size of the printer might limit the size of the final product. Additionally, the post-processing steps involved can add to the overall production time.

Applications of Titanium Alloy 3D Printing

The applications of 3D printed titanium alloys are as diverse as they are exciting. Let’s explore some key areas where this technology is making a real difference:

- Aerospace: From lightweight aircraft components to complex engine parts, titanium alloy 3D printing is helping to create lighter, stronger, and more fuel-efficient airplanes. Imagine a future where commercial flights are smoother, quieter, and more environmentally friendly, thanks in part to these innovative materials.

- Medical Implants: Remember how we discussed pure titanium’s biocompatibility? Well, 3D printing allows for the creation of custom-designed implants that perfectly match a patient’s anatomy. This can lead to faster healing times, improved functionality, and a better overall patient experience.

- Motorsports: The relentless pursuit of speed and performance in motorsports finds a perfect partner in 3D printed titanium alloys. Components like pistons, connecting rods, and suspension parts can be meticulously crafted to be lighter and stronger, shaving off precious milliseconds and giving race teams a competitive edge.

- Consumer Goods: While 3D printed titanium alloys might not be adorning your kitchen countertop just yet, they’re making inroads into the world of high-end consumer goods. Think about premium bicycles with incredibly lightweight and strong frames, or custom-designed prosthetics that are not only functional but also aesthetically pleasing. As the technology matures and costs come down, we can expect to see even more innovative consumer applications emerge.

- Emerging Frontiers: The possibilities for 3D printed titanium alloys extend beyond traditional industries. Researchers are exploring their use in creating lightweight and robust components for prosthetics and robotic limbs, pushing the boundaries of human potential. Additionally, the ability to create intricate internal channels makes this technology well-suited for applications like heat exchangers and microfluidic devices, paving the way for advancements in fields like renewable energy and bioengineering.

Exploring Different Titanium Alloy Powders

Not all titanium alloy powders are created equal. Just like the spices in your kitchen, different alloying elements and powder characteristics can significantly impact the final product. Here are some key factors to consider:

- Alloy Composition: As mentioned earlier, the specific elements added to pure titanium will influence the properties of the final product. Popular choices include aluminum (Al), vanadium (V), and molybdenum (Mo), each offering unique benefits in terms of strength, corrosion resistance, and biocompatibility.

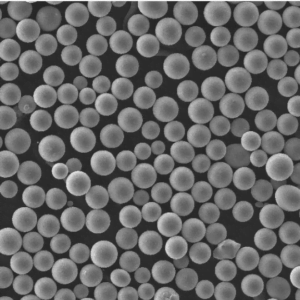

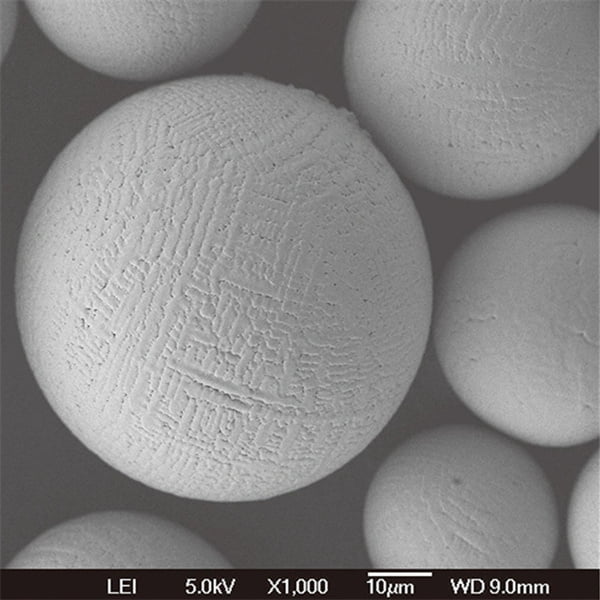

- Powder Particle Size and Shape: The size and shape of the titanium alloy powder particles play a crucial role in the 3D printing process. Finer powders generally lead to smoother surface finishes, while larger particles might be more suitable for applications requiring higher build rates. The ideal powder shape is typically spherical, as this ensures optimal flow and packing during the printing process.

- Powder Flowability: Imagine trying to bake a cake with clumpy flour. The same concept applies to 3D printing. The powder needs to flow freely and consistently for the printer to lay down each layer precisely. Manufacturers meticulously control the powder’s flowability characteristics to ensure a smooth and efficient printing process.

-

Stainless Steel 316L Powder for Metal 3D Printing

Stainless Steel 316L Powder for Metal 3D Printing -

Ti6Al4V Powder Titanium Based Metal Powder for Additive Manufacturing

Ti6Al4V Powder Titanium Based Metal Powder for Additive Manufacturing -

CoCrMoW Powder

CoCrMoW Powder -

CoCr28Mo6 Powder

CoCr28Mo6 Powder -

Haynes alloy 188 powder

Haynes alloy 188 powder -

Best 17-4PH stainless steel powder for 3D Printing

Best 17-4PH stainless steel powder for 3D Printing -

304L Stainless Steel Powder for MIM

304L Stainless Steel Powder for MIM -

17-4PH Stainless Steel Metal Powder for MIM

17-4PH Stainless Steel Metal Powder for MIM -

316L Stainless Steel Powder for MIM

316L Stainless Steel Powder for MIM

Understanding the Costs and Considerations

3D printing titanium alloys offers a treasure trove of benefits, but it’s essential to be aware of the associated considerations. Here’s a breakdown of some key points:

- Cost: Compared to traditional manufacturing methods, 3D printing titanium alloys can be more expensive. The cost of the powder itself is a significant factor, and the printing process can be time-consuming, especially for larger or more complex parts.

- Build Size Limitations: Current 3D printers have limitations on the size of the objects they can produce. This might restrict the use of this technology for certain large-scale applications.

- Post-Processing: Once the printing process is complete, the part might require additional finishing steps like heat treatment or surface machining to achieve the desired properties. These post-processing steps can add to the overall production time and cost.

However, the potential benefits often outweigh the initial investment. The design freedom, lightweighting capabilities, and reduced waste associated with 3D printing can lead to significant cost savings in the long run, especially for applications where performance is critical. Additionally, as the technology matures and production scales up, we can expect the cost of 3D printed titanium alloys to become more competitive.

FAQ

Q: Is 3D printed titanium as strong as traditional machined titanium?

A: Yes, 3D printed titanium alloys can achieve similar or even superior strength compared to traditionally machined titanium. The strength depends on the specific alloy composition and the 3D printing process parameters.

Q: What are some of the challenges associated with 3D printing titanium alloys?

A: Cost, build size limitations, and post-processing requirements are some of the key challenges. However, ongoing advancements in technology are continuously addressing these limitations.

Q: What are the environmental benefits of 3D printing titanium alloys?

A: Compared to traditional methods that involve significant material removal, 3D printing utilizes only the necessary material, minimizing waste. Additionally, the lightweighting capabilities of 3D printed components can lead to reduced fuel consumption in applications like aerospace.

The Future of Titanium Alloy 3D Printing

The future of 3D printed titanium alloys is brimming with possibilities that extend far beyond the applications we’ve explored so far. Here’s a peek into what’s on the horizon:

- Reduced Costs and Increased Adoption: As 3D printing technology continues to evolve, production processes become more efficient, and powder costs decrease, we can expect to see a significant drop in the overall cost of 3D printed titanium alloys. This will open doors for even wider adoption across various industries, making this transformative technology more accessible than ever before.

- Advanced Printing Techniques: Innovation in 3D printing techniques is happening at a rapid pace. The development of multi-material printing holds immense promise. Imagine seamlessly integrating different materials within a single print, allowing for the creation of objects with even more customized properties. For instance, a medical implant could be crafted with a biocompatible titanium core surrounded by a porous outer layer that promotes bone ingrowth.

- On-Demand Manufacturing: The ability to 3D print titanium alloys on-demand, potentially even at the point of use, could revolutionize supply chains and logistics. Think about spare parts for aircrafts being printed on-site, minimizing downtime and delays. This kind of flexibility and efficiency has the potential to transform various sectors.

- Bioprinting Revolution: The field of bioprinting, which utilizes 3D printing techniques to create living tissues and organs, holds immense promise for the future of medicine. Titanium alloys, with their biocompatible nature, could play a crucial role in creating scaffolds that support tissue growth and regeneration. This technology has the potential to revolutionize the treatment of organ failure and other debilitating conditions.

Conclusion

Titanium alloy 3D printed metal powder represents a powerful confluence of cutting-edge materials science and transformative manufacturing techniques. With its unique combination of strength, lightweighting capabilities, and design freedom, this technology is poised to shape the future across diverse industries. From revolutionizing aerospace and medicine to enabling on-demand manufacturing and bioprinting breakthroughs, the possibilities are truly limitless. As we continue to explore the potential of 3D printed titanium alloys, we can be certain that this remarkable material will continue to surprise and inspire us for years to come.

Share On

MET3DP Technology Co., LTD is a leading provider of additive manufacturing solutions headquartered in Qingdao, China. Our company specializes in 3D printing equipment and high-performance metal powders for industrial applications.

Inquiry to get best price and customized Solution for your business!

Related Articles

About Met3DP

Recent Update

Our Product

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731