Best in718 powder inconel 718 powder for metal 3D printing

inconel 718 powder price list

| Metal Powder | Size | Quantity | Price/kg | Size | Quantity | Price/kg |

| Inconel 718 powder | 0-20μm | 1KG | 60.9 | 53-105μm | 1KG | 59 |

| 10KG | 39.8 | 10KG | 38 | |||

| 100KG | 34.5 | 100KG | 33 |

Low MOQ

Provide low minimum order quantity to meet different needs.

OEM & ODM

Provide customized products and design services to meet unique customer needs.

Adequate Stock

Ensure fast order processing and provide reliable and efficient service.

Customer Satisfaction

Provide high quality products with customer satisfaction at the core.

share this product

Table of Contents

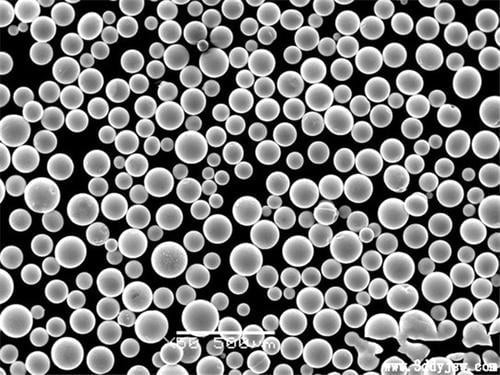

inconel 718 powder Overview

Inconel 718 powder is a high-performance alloy powder used in additive manufacturing (AM) processes, such as laser powder bed fusion (LPBF) and electron beam powder bed fusion (EBPBF). It is renowned for its exceptional strength, corrosion resistance, and high-temperature capabilities. Inconel 718 powder is widely employed in demanding industries like aerospace, energy, and medical.

inconel 718 powder Composition and Characteristics

Inconel 718 powder is an alloy primarily composed of nickel (Ni), chromium (Cr), iron (Fe), and niobium (Nb). Its specific composition varies slightly depending on the manufacturer and application requirements. The table below highlights the typical composition and characteristics of Inconel 718 powder:

| Property | Value |

|---|---|

| Nickel (Ni) | 50-55% |

| Chromium (Cr) | 17-21% |

| Iron (Fe) | 17-21% |

| Niobium (Nb) | 4.75-5.5% |

| Molybdenum (Mo) | 2.8-3.3% |

| Titanium (Ti) | 0.65-1.15% |

| Aluminum (Al) | 0.2-0.8% |

| Carbon (C) | 0.08% max |

| Silicon (Si) | 0.35% max |

| Manganese (Mn) | 0.35% max |

| Sulfur (S) | 0.015% max |

| Phosphorus (P) | 0.015% max |

inconel 718 powder Applications

Inconel 718 powder finds applications in various industries due to its unique properties. Some of its key applications include:

| Industry | Applications |

|---|---|

| Aerospace | Turbine blades, engine components, structural parts |

| Energy | Gas turbine components, heat exchangers, pressure vessels |

| Medical | Surgical instruments, implants, dental prosthetics |

| Automotive | High-performance engine components, exhaust systems |

| Defense | Armor, weapons, aerospace components |

Specifications, Sizes, and Grades

Inconel 718 powder is available in various specifications, sizes, and grades to meet specific application requirements. The table below provides an overview of these parameters:

| Parameter | Details |

|---|---|

| Specifications | ASTM B163, AMS 5848, ISO 2076 |

| Sizes | 15-150 microns (typical) |

| Grades | Inconel 718, Inconel 718Plus |

inconel 718 powder Suppliers and Pricing

Several suppliers offer Inconel 718 powder in the market. The price of the powder can vary depending on factors such as quantity, grade, and supplier. The table below provides a comparison of prices from different suppliers:

| Supplier | Price Range |

|---|---|

| Met3DP | $100-$200 per kilogram |

| Praxair | $120-$220 per kilogram |

| Carpenter Technology | $150-$250 per kilogram |

| ATI | $180-$280 per kilogram |

Met3dp inconel 718 powder price

| Metal Powder | Size | Quantity | Price/kg | Size | Quantity | Price/kg |

| Inconel 718 | 0-20μm | 1KG | 60.9 | 53-105μm | 1KG | 59 |

| 10KG | 39.8 | 10KG | 38 | |||

| 100KG | 34.5 | 100KG | 33 |

in718 powder Pros and Cons

Like any material, Inconel 718 powder has its advantages and disadvantages. The table below summarizes the pros and cons:

| Pros | Cons |

|---|---|

| High strength and hardness | Expensive compared to other alloys |

| Excellent corrosion resistance | Difficult to machine |

| High-temperature capabilities | Requires specialized welding techniques |

| Good weldability and formability | Can be susceptible to stress corrosion cracking |

IN718 powder Specific Metal Powder Models

Various metal powder models of Inconel 718 are available in the market. Some of the notable models include:

- Met3DP Inconel 718: Optimized for LPBF and EBPBF processes, offering high density and excellent mechanical properties.

- Praxair Incoloy 718: Designed for LPBF applications, known for its fine particle size and consistent flowability.

- Carpenter Technology Carpenter 718: Suitable for both LPBF and EBPBF, providing high strength and corrosion resistance.

- ATI 718Plus: Developed for LPBF, featuring improved strength and ductility compared to standard Inconel 718.

- Sandvik Osprey 718: Produced using the Osprey process, resulting in spherical particles with high flowability and packing density.

- Höganäs AM 718: Optimized for LPBF, offering high density and excellent mechanical properties.

- LPW Technology LPW 718: Specifically designed for LPBF, known for its consistent particle size and low oxygen content.

- Arcam AB Arcam 718: Suitable for EBPBF, offering high density and fine particle size.

- Renishaw RenAM 718: Developed for LPBF, providing high strength and corrosion resistance.

- EOS GmbH EOS 718: Optimized for LPBF, known for its high density and excellent surface finish.

FAQ

Q: What is the difference between Inconel 718 powder and other nickel-based alloys?

A: Inconel 718 powder is known for its exceptional strength, corrosion resistance, and high-temperature capabilities compared to other nickel-based alloys. It contains a higher percentage of chromium, which contributes to its enhanced corrosion resistance.

Q: How is Inconel 718 powder used in additive manufacturing?

A: Inconel 718 powder is used in LPBF and EBPBF processes. In LPBF, a laser beam selectively melts the powder particles to create the desired shape, while in EBPBF, an electron beam is used for melting.

Q: What are the advantages of using Inconel 718 powder in AM?

A: Using Inconel 718 powder in AM offers advantages such as design flexibility, reduced lead times, and the ability to create complex geometries. It also allows for the production of lightweight components with high strength and durability.

Q: What are the future trends in Inconel 718 powder technology?

A: Research and development efforts are focused on improving the powder’s flowability, packing density, and mechanical properties. Additionally, there is a growing interest in developing new alloys based on Inconel 718 with enhanced performance characteristics.

Get Latest Price

About Met3DP

Product Category

HOT SALE

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731