Haynes alloy 188 powder

Haynes Alloy 188 powder is a nickel-based superalloy renowned for its excellent resistance to high-temperature environments, corrosion, and oxidation. It exhibits remarkable strength, ductility, and creep resistance, making it ideal for applications in extreme conditions.

Low MOQ

Provide low minimum order quantity to meet different needs.

OEM & ODM

Provide customized products and design services to meet unique customer needs.

Adequate Stock

Ensure fast order processing and provide reliable and efficient service.

Customer Satisfaction

Provide high quality products with customer satisfaction at the core.

share this product

Table of Contents

Overview of Haynes Alloy 188 Powder

Haynes alloy 188 is a high-performance superalloy exhibiting excellent resistance to oxidation, thermal fatigue and creep at temperatures exceeding 1000°C. The high levels of cobalt, nickel, chromium and tungsten impart exceptional high temperature strength and corrosion resistance.

Key characteristics of Haynes 188 powder include:

- Outstanding high temperature strength and creep resistance

- Excellent oxidation and corrosion resistance

- Retains strength during prolonged thermal cycling

- Resists sulfur and vanadium attack

- Good fabrication characteristics

- Available in range of powder sizes and shapes

Haynes 188 powder is designed for extremely demanding applications in aviation, chemical processing, power generation, and heat treating industries needing extraordinary performance at high temperatures.

Chemical Composition of Haynes Alloy 188 Powder

The typical composition of Haynes 188 powder is:

| Element | Weight % |

|---|---|

| Nickel (Ni) | Balance |

| Cobalt (Co) | 20-25% |

| Chromium (Cr) | 20-25% |

| Tungsten (W) | 12-15% |

| Iron (Fe) | <3% |

| Manganese (Mn) | <1.5% |

| Silicon (Si) | <1% |

| Carbon (C) | <0.1% |

Nickel provides the matrix while cobalt imparts strength. Chromium and tungsten provide excellent oxidation and corrosion resistance. Iron, manganese and silicon are present as impurities.

Properties of Haynes Alloy 188 Powder

Key properties of Haynes 188 powder include:

| Property | Value |

|---|---|

| Density | 8.5 g/cm3 |

| Melting Point | 1230-1260°C |

| Thermal Conductivity | 9.8 W/m·K |

| Electrical Resistivity | 126 μΩ·cm |

| Young’s Modulus | 205 GPa |

| Poisson’s Ratio | 0.31 |

| Tensile Strength | 550-900 MPa |

| Yield Strength | 240-650 MPa |

| Elongation | 25-45% |

| Fatigue Strength | 310 MPa |

The properties like strength, ductility and fatigue resistance are maintained at extreme temperatures exceeding 1000°C making it suitable for the most demanding high temperature applications.

Production Method for Haynes Alloy 188 Powder

Haynes 188 powder is produced using:

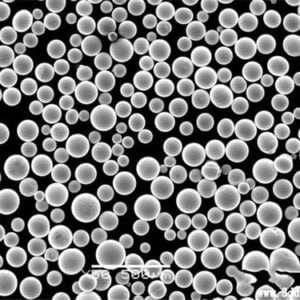

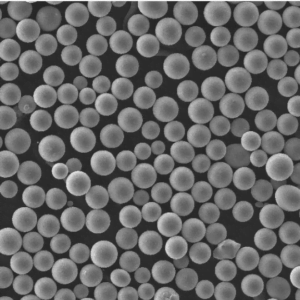

- Gas Atomization – High pressure inert gas jet used to disintegrate molten alloy stream into fine spherical powders. Provides good flow and packing.

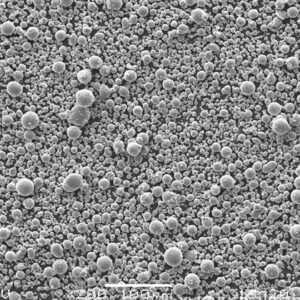

- Water Atomization – High velocity water jet impacts the molten stream to produce fine irregular powders. More economical but higher oxygen pickup.

- Inert Gas Condensation – Vaporization and controlled condensation of alloying elements in high purity inert gas environment. Yields ultrafine spherical powder.

Gas atomization provides the best control over particle size distribution, shape and purity.

Applications of Haynes Alloy 188 Powder

Typical applications of Haynes 188 powder include:

- Additive Manufacturing – Used in selective laser melting, electron beam melting to produce complex parts for extreme environments.

- Thermal Spray Coatings – Deposited using plasma or HVOF spraying to provide wear and corrosion resistance at high temperatures.

- Brazing Filler – For joining components that must withstand high temperatures during service.

- Solid Fuel Igniters – Powder metallurgy igniter plugs used in jet engines, land based turbines.

- Molten Metal Processing – Handling tundishes, conveying components, melt pots used in glass, aluminum and metal industries.

- Furnace Components – Trays, fixtures, conveyors used in high temperature heat treatment and glass furnaces.

Specifications of Haynes Alloy 188 Powder

Haynes 188 powder is available in various size ranges, shapes and grades including:

- Particle Size: From 10-45 microns for AM methods, up to 120 microns for thermal spray processes.

- Morphology: Spherical, irregular and blended powder shapes. Smooth spherical powder provides better flow.

- Purity: Ranging from commercial to ultra high purity grades based on stringent chemical analysis.

- Grades: Conforming to AMS 5758, AMS 5759, AMS 5864 standards tailored for aerospace applications.

- Surface Area: Powders with low surface area preferred to minimize oxidation.

Global Suppliers of Haynes Alloy 188 Powder

Some of the major global suppliers are:

- Carpenter Additive (USA)

- Sandvik Osprey (UK)

- Erasteel (France)

- Edgetech Industries (USA)

- Special Metals Corp. (USA)

- Tekna (Canada)

These companies produce various grades of Haynes 188 powder tailored for additive manufacturing, thermal spray coatings, and other high temperature applications.

Pricing of Haynes Alloy 188 Powder

Pricing of Haynes 188 powder depends on factors like:

- Purity levels

- Particle size distribution and shape

- Order quantity

- Manufacturer and geographical location

| Grade | Price Range |

|---|---|

| Commercial | $80-120 per kg |

| High purity | $120-250 per kg |

| Ultrafine | $250-450 per kg |

| Special grade | $450-850 per kg |

Gas atomized ultrafine and high purity powders demand premium pricing over commercial grades. Smaller quantities are costlier.

Storage and Handling of Haynes Alloy 188 Powder

Haynes 188 powder requires careful storage and handling:

- Should be stored in sealed containers under inert gas to prevent oxidation

- Avoid accumulation of fine powders to minimize dust explosion risk

- Wear personal protective equipment when handling fine powder

- Follow recommended safety practices from manufacturer

Proper grounding, ventilation and PPE must be used when handling this reactive alloy powder.

Inspection and Testing of Haynes Alloy 188 Powder

Key tests carried out for quality control include:

- Chemical analysis using OES or XRF to ensure composition is within specified limits.

- Particle size distribution using laser diffraction technique per ASTM B822 standard.

- Morphology analysis through scanning electron microscopy.

- Powder flow rate measurement as per ASTM B213 standard using Hall flowmeter.

- Density measurement using helium pycnometry.

- Impurity levels tested through ICP-MS.

- Microstructure characterization by X-ray diffraction.

Thorough inspection and testing verifies that the powder meets the chemical, physical and microstructural requirements for the intended application.

Comparison Between Haynes 188 and Hastelloy X Powders

Haynes 188 and Hastelloy X are two nickel-based alloy powders compared:

| Parameter | Haynes 188 | Hastelloy X |

|---|---|---|

| Base element | Nickel | Nickel |

| Cr content | 22-25% | 22-25% |

| Mo content | No molybdenum | 8-10% |

| Oxidation resistance | Excellent up to 1204°C | Excellent up to 1150°C |

| Cost | Higher | Lower |

| Strength | Lower | Higher |

| Workability | Excellent | Moderate |

| Applications | Coatings, braze filler | Aerospace components, springs |

Haynes 188 offers better workability while Hastelloy X has higher strength. Haynes 188 resists oxidation at extremely high temperatures.

Haynes Alloy 188 Powder FAQs

Q: How is Haynes alloy 188 powder produced?

A: Haynes 188 powder is commercially produced using gas atomization, water atomization, and inert gas condensation techniques. Gas atomization offers the best control over particle characteristics.

Q: What are the main applications for Haynes 188 powder?

A: Key applications are additive manufacturing, thermal spray coatings, brazing filler material, powder metallurgy igniter plugs, and high temperature furnace components needing extraordinary oxidation and corrosion resistance.

Q: What is the recommended powder size for AM or thermal spray?

A: For additive manufacturing, the ideal size range is 15-45 microns. For thermal spray coatings, a coarser powder up to 120 microns is preferred.

Q: Does Haynes 188 powder require special handling precautions?

A: Yes, it is recommended to handle this reactive alloy powder carefully under inert atmosphere using proper grounding, ventilation and PPE.

Q: Where can I purchase Haynes 188 powder suitable for aerospace applications?

A: High purity Haynes 188 powder meeting aerospace standards can be sourced from leading manufacturers like Carpenter Additive, Sandvik Osprey, Erasteel, and Special Metals Corporation.

Get Latest Price

About Met3DP

Product Category

HOT SALE

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731