Niobium Powder

Niobium is used in prosthetics and implant devices, such as pacemakers because it is physiologically inert and hypoallergenic. Besides, niobium powders are required as a raw material, in the fabrication of electrolytic capacitors.

Low MOQ

Provide low minimum order quantity to meet different needs.

OEM & ODM

Provide customized products and design services to meet unique customer needs.

Adequate Stock

Ensure fast order processing and provide reliable and efficient service.

Customer Satisfaction

Provide high quality products with customer satisfaction at the core.

share this product

Table of Contents

Overview of Niobium Powder

Niobium is a shiny, white refractory transition metal with outstanding heat resistance and very high melting point. In powder form, it exhibits excellent thermal, electrical, and chemical stability.

Key properties of niobium powder include:

- High heat resistance and refractory nature

- Excellent corrosion resistance

- Superconducting below 9.2K (-264°C)

- Thermal and electrical stability

- Low neutron absorption

- High density powder with good chemical purity

- Available in various particle size ranges

Niobium powder is used where its refractory, conductive, and superconductive properties can be utilized. The major applications include electronics, superconductors, alloys, chemical/heat resistant components, optical coatings, and pyrotechnics.

Composition of Niobium Powder

Niobium powder has the following typical composition:

| Element | Purity |

|---|---|

| Niobium (Nb) | 99% min |

| Tantalum (Ta) | 0.5% max |

| Hafnium (Hf) | 0.01% max |

| Nitrogen (N) | 0.03% max |

| Carbon (C) | 0.05% max |

| Oxygen (O) | 0.1-0.2% |

| Hydrogen (H) | 0.0015% max |

High purity niobium powder contains over 99% niobium metal with low impurity levels. Commercial grades have higher permissible impurities.

Properties of Niobium Powder

Niobium powder exhibits the following properties:

| Property | Value |

|---|---|

| Density | 8.57 g/cm3 |

| Melting Point | 2477°C |

| Thermal Conductivity | 53 W/m∙K |

| Electrical Resistivity | 15 μΩ∙cm |

| Young’s Modulus | 105 GPa |

| Poisson’s Ratio | 0.40 |

| Tensile Strength | 550 MPa |

| Compressive Strength | 200 MPa |

| Vickers Hardness | 600 HV |

Niobium has extremely high melting point and very good conductivity. It offers high strength at low and high temperatures. The superconducting transition temperature is 9.2K.

Production Methods for Niobium Powder

Niobium powder can be produced by methods like:

- Hydriding-Dehydriding – Niobium ingots crushed into coarse powder and hydrided. The niobium hydride is vacuum dehydrided and milled into fine powder.

- Calciothermic Reduction – Reduction of niobium oxide with calcium followed by consolidation and crushing to powder.

- Electrolysis – Molten salt electrolysis of niobium oxide to produce niobium sponge which is crushed into powder.

- Carbon Reduction – Niobium oxide is reduced with carbon and processed into powder.

The hydriding process is most common but carbon and electrothermal reduction offer higher purity powder.

Applications of Niobium Powder

Niobium powder is used in the following major applications:

- Electronics – Capacitors, superconducting radio frequency cavities, Josephson junctions, integrated circuits.

- Metal Alloys – Added to steels and nickel-based alloys for strength and heat resistance.

- Coatings and Paints – Used in conductive coatings, spark-resistant paints, optical coatings.

- Welding – As filler material for stainless steel, nickel alloys, and refractory metals.

- Chemical Industry – Components like heat exchangers, reactors vessels utilizing niobium’s stability.

- Pyrotechnics – As fuel and oxidizer in pyrotechnic formulations.

Specifications of Niobium Powder

Niobium powder is available under various specifications:

- Purity Grades – From commercial purity to ultra high purity (99.99%) based on impurities.

- Particle Sizes – Ranging from 1 micron to 150 microns for various applications.

- Morphology – Irregular, spherical, nodular and flaked powder shapes.

- Surface Area – From low surface area up to high surface area powder grades.

- Oxygen Content – Low oxygen fine powder grades also available.

- Custom Grades – Customer specific particle characteristics and purity.

Global Suppliers of Niobium Powder

Some of the major global niobium powder suppliers include:

- H.C. Starck (Germany)

- CBMM (Brazil)

- Niobec (Canada)

- ESPI Metals (USA)

- Continental Steel & Tube (USA)

- ZhuZhou Oriental Powder Metallurgy (China)

These companies produce various niobium powder grades using different production methods at commercial to high purity levels.

Pricing of Niobium Powder

Niobium powder prices depend on factors like:

- Purity Grade – From $50/kg for commercial purity to over $500/kg for ultra high purity grades.

- Particle Size – Nanoscale and sub-micron powders are higher priced.

- Morphology – Spherical and smooth powders command premium pricing.

- Quantity – Prices reduce for bulk quantities due to economy of scale.

- Manufacturer – Major global suppliers offer more competitive pricing.

- Geography – Prices vary in different world regions.

Storage and Handling of Niobium Powder

Niobium powder requires controlled storage and handling to:

- Prevent exposure to air and moisture to minimize oxidation

- Avoid ignition and explosion hazards from fine powder

- Use appropriate ventilation and respiratory protection during handling

- Follow precautions in Safety Data Sheet from supplier

- Store sealed containes in a cool, dry place away from incompatibles

Inert gas glove boxes, proper grounding and PPE should be used when handling niobium powder.

Inspection and Testing of Niobium Powder

The following inspections and tests are typically performed on niobium powder:

- Chemical Analysis – Inductively coupled plasma or X-ray fluorescence techniques used for composition and purity check.

- Particle Size Testing – Carried out as per ASTM B822 standard using laser diffraction technique.

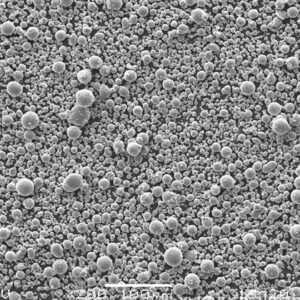

- Morphology – Scanning electron microscopy used for determining shape and surface area.

- Specific Surface Area – BET gas absorption method used for measuring surface area per unit mass.

- Impurities Testing – ICP-MS used to quantify levels of tantalum, oxygen, nitrogen and other impurities.

- Powder Flow – Tested using Hall flowmeter as per ASTM B213 standard.

Comparison of Niobium and Tantalum Powder

Niobium and tantalum powders are two similar refractory metal powders compared:

| Parameter | Niobium Powder | Tantalum Powder |

|---|---|---|

| Density | 8.57 g/cm3 | 16.6 g/cm3 |

| Melting Point | 2477°C | 2996°C |

| Electrical resistivity | 15 μΩ.cm | 13 μΩ.cm |

| Tensile strength | 550 MPa | 400 MPa |

| Oxidation resistance | Moderate | Better |

| Cost | Lower | Higher |

| Applications | Alloys, capacitors | Medical, electronics |

Tantalum has higher density, melting point, and better oxidation resistance but is more expensive than niobium.

Niobium Powder FAQs

Q: How is niobium powder produced?

A: The main production methods for niobium powder are hydriding-dehydriding, calciothermic reduction, electrolysis, and carbon reduction of niobium oxide sources.

Q: What is niobium powder used for?

A: Major applications of niobium powder include electronics, metal alloys, coatings, chemical industry, welding, pyrotechnics, and superconductors.

Q: What is the typical niobium powder size for thermal spray coatings?

A: For thermal spray processes, niobium powder is typically used in particle size ranges of 45-150 microns. Finer powder can lead to oxidation issues.

Q: Is niobium powder flammable or explosive?

A: Yes, like other finely divided metals, niobium powder can potentially be flammable or explosive. Proper precautions are needed for safe handling and storage.

Q: Where can I buy high purity niobium powder for superconducting applications?

A: Ultra high purity (99.99%) niobium powder suitable for superconducting applications can be purchased from major suppliers including HC Starck, CBMM, and ESPI Metals.

Get Latest Price

About Met3DP

Product Category

HOT SALE

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731