AlSi7Mg powder

AlSi7Mg powder is an aluminum alloy powder that primarily consists of aluminum (Al), silicon (Si), and magnesium (Mg). The “7” in its name signifies the percentage of silicon, while “Mg” represents the magnesium content. This powder exhibits excellent strength, low density, and impressive thermal properties, making it a preferred choice in multiple industries.

Low MOQ

Provide low minimum order quantity to meet different needs.

OEM & ODM

Provide customized products and design services to meet unique customer needs.

Adequate Stock

Ensure fast order processing and provide reliable and efficient service.

Customer Satisfaction

Provide high quality products with customer satisfaction at the core.

share this product

Table of Contents

Overview of AlSi7Mg Powder

AlSi7Mg or A357 alloy is a versatile foundry alloy that possesses properties between pure aluminum and high-silicon hypereutectic alloys. The silicon additions improve castability and enhance mechanical properties while magnesium improves strength.

Key characteristics of AlSi7Mg powder include:

- Good strength and hardness

- Excellent fluidity and castability

- Good machinability and polishability

- High thermal conductivity

- Good corrosion resistance

- Low coefficient of thermal expansion

- Available in range of particle sizes

AlSi7Mg powder is used for producing automotive components, hydraulic parts, and other precision castings needing balanced properties.

Chemical Composition of AlSi7Mg Powder

The typical chemical composition of AlSi7Mg powder is:

| Element | Weight % |

|---|---|

| Aluminum (Al) | Balance |

| Silicon (Si) | 6-8% |

| Magnesium (Mg) | 0.4-0.8% |

| Iron (Fe) | 0.15-0.5% |

| Manganese (Mn) | 0.1% max |

| Copper (Cu) | 0.1% max |

| Zinc (Zn) | 0.1% max |

| Titanium (Ti) | 0.25% max |

Silicon is the principal alloying element while magnesium enhances strength and castability. Iron, manganese, and titanium have minor effects. The composition is tailored to meet mechanical property requirements.

Properties of AlSi7Mg Powder

AlSi7Mg powder possesses the following properties:

| Property | Value |

|---|---|

| Density | 2.68 g/cm3 |

| Melting Point | ~600°C |

| Thermal Conductivity | 130-160 W/mK |

| Electrical Resistivity | 3-5 μΩ.cm |

| Young’s Modulus | 70-80 GPa |

| Poisson’s Ratio | 0.33 |

| Tensile Strength | 250-300 MPa |

| Yield Strength | 140-180 MPa |

| Elongation | 4-8% |

| Hardness | 80-100 Brinell |

The silicon additions increase the strength while retaining good ductility and machinability. The alloy has excellent castability and thermal properties.

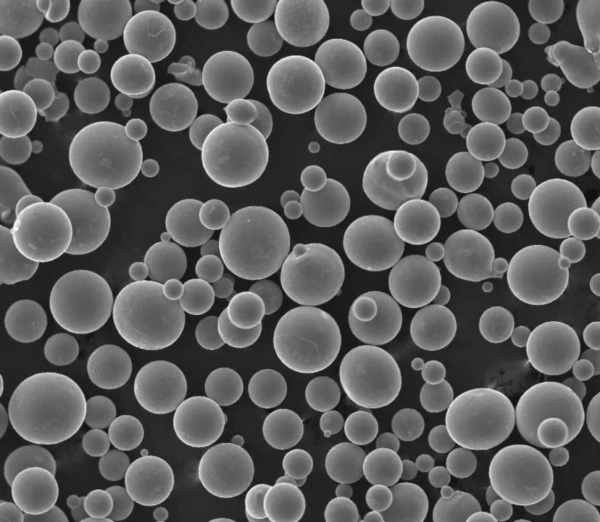

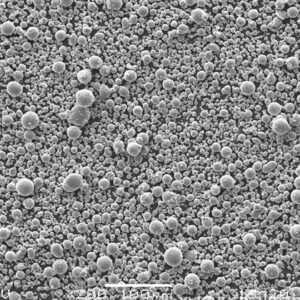

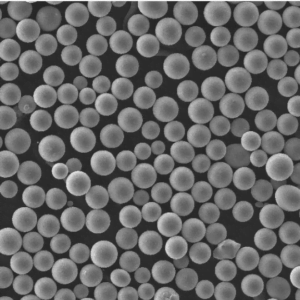

Production Method of AlSi7Mg Powder

Commercial production processes used for AlSi7Mg powder include:

- Gas Atomization – Molten alloy stream broken into fine droplets by inert gas jets. Produces spherical powder.

- Water Atomization – High pressure water jet impacts molten metal to yield fine powders. Cost effective but higher oxygen pickup.

- Mechanical Alloying – Ball milling of aluminum and silicon powders followed by cold compaction and sintering.

Gas atomization provides the most control over powder characteristics like particle size distribution, morphology, and microstructure.

Applications of AlSi7Mg Powder

The key applications of AlSi7Mg powder include:

- Metal Injection Molding – To manufacture small intricate parts with tight tolerances and good mechanical properties.

- Additive Manufacturing – Used in binder jetting, laser melting and other AM processes to produce complex components.

- Castings – Added to melts to improve fluidity. Used to manufacture automotive parts requiring durability.

- Powder Metallurgy – Press and sinter process to create high performance parts.

- Thermal Spraying – Deposited as protective coatings on metal surfaces to provide wear and corrosion resistance.

- Welding Filler – For joining aluminum components while retaining weld strength.

- Pyrotechnics – Added to pyrotechnic compositions as a fuel constituent.

Specifications of AlSi7Mg Powder

AlSi7Mg powder is available under different size ranges, grades and purity levels:

- Particle Size: From 10 – 150 microns for AM, under 45 microns for MIM.

- Morphology: Spherical, granular and irregular particle shapes. Smooth powder flows better.

- Purity: From commercial to high purity (99.9%) grades.

- Oxygen Content: Levels range from 400 – 1500 ppm for different production methods.

- Flowability: Powder customized for excellent flow rates of 25 s/50 g or better.

- Grades: Custom alloy chemistry and powder characteristics offered.

Global Suppliers of AlSi7Mg Powder

Some of the major AlSi7Mg powder suppliers globally are:

- PyroGenesis Canada

- Sandvik Osprey UK

- Valimet Inc. USA

- Makin Metal Powders UK

- Shanghai Chaowei Nanotechnology China

- Agni Metal USA

- Titanium Powder Canada

These companies produce AlSi7Mg powder using various methods suitable for additive manufacturing, metal injection molding, thermal spray, and other applications.

AlSi7Mg Powder Pricing

Pricing of AlSi7Mg powder depends on factors like:

- Purity levels

- Particle characteristics

- Production method

- Order volume

- Additional processing

- Supplier and location

| Grade | Price Range |

|---|---|

| Commercial | $5-15 per kg |

| High purity | $15-30 per kg |

| Ultrafine | $30-60 per kg |

| Special grade | $50-120 per kg |

In general, gas atomized and controlled powders command much higher pricing than simple commercial grades.

Handling and Storage of AlSi7Mg Powder

AlSi7Mg powder should be properly handled and stored to prevent:

- Moisture contact leading to oxidation

- Fire hazards from dust accumulation

- Health hazards from inhaling fine powders

- Safety practices recommended by supplier should be followed

Sealed containers under inert atmosphere along with proper grounding and PPE is recommended.

Testing and Characterization Methods

Key test methods for AlSi7Mg powder include:

- Chemical analysis using OES or XRF for composition

- Particle size distribution as per ASTM B822 standard

- Morphology analysis through SEM

- Flow rate measurement using Hall flowmeter

- Density determination by helium pycnometry

- Impurity levels tested by ICP-MS

- Microstructure examined by XRD phase analysis

Thorough testing ensures powder quality for application requirements is met.

Comparison of AlSi7Mg and AlSi10Mg Powders

AlSi7Mg and AlSi10Mg are two aluminum alloy powders compared:

| Parameter | AlSi7Mg | AlSi10Mg |

|---|---|---|

| Silicon content | 6-8% | 9-11% |

| Strength | Lower | Higher |

| Castability | Comparable | Comparable |

| Corrosion resistance | Good | Excellent |

| Cost | Lower | Higher |

| Applications | Castings, MIM | Aerospace, AM parts |

| Availability | Readily available | Moderate |

AlSi10Mg offers higher strength but at increased cost. AlSi7Mg provides well-balanced properties at lower cost where high strength is not critical.

AlSi7Mg Powder FAQs

Q: How is AlSi7Mg powder produced?

A: AlSi7Mg powder is commercially produced using gas atomization, water atomization, or mechanical alloying followed by sintering. Gas atomization offers better control over particle characteristics.

Q: What are the main applications for AlSi7Mg powder?

A: The key applications for AlSi7Mg powder include metal injection molding, aluminum die casting, additive manufacturing, powder metallurgy, thermal spray coatings, and filler welding wire.

Q: What is the typical particle size used for AlSi7Mg powder in AM?

A: For most metal 3D printing processes like DMLS and binder jetting, the common particle size range for AlSi7Mg powder is 20-45 microns.

Q: Does AlSi7Mg powder require any special handling precautions?

A: Yes, it is recommended to handle aluminum powders under inert atmosphere using proper grounding, ventilation, and PPE to prevent fire and explosion hazards.

Q: Where can I buy AlSi7Mg powder suitable for making precision castings?

A: Leading powder suppliers like Valimet, Makin Metal Powders, and PyroGenesis provide AlSi7Mg powder suitable for foundry applications like precision castings.

Get Latest Price

About Met3DP

Product Category

HOT SALE

CONTACT US

Any questions? Send us message now! We’ll serve your request with a whole team after receiving your message.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731