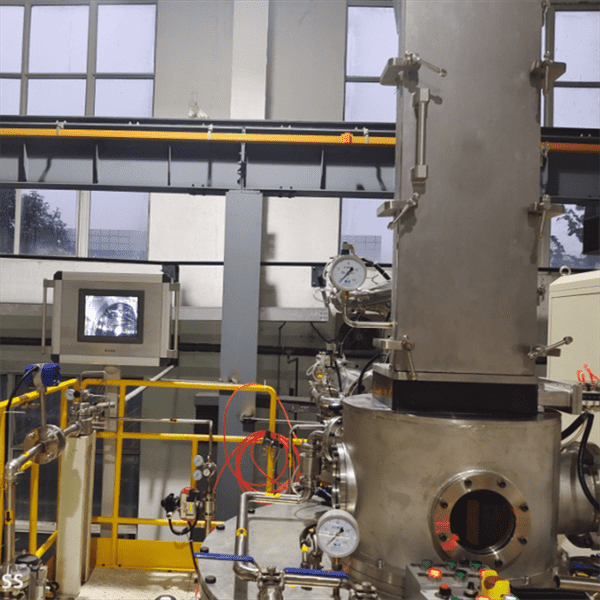

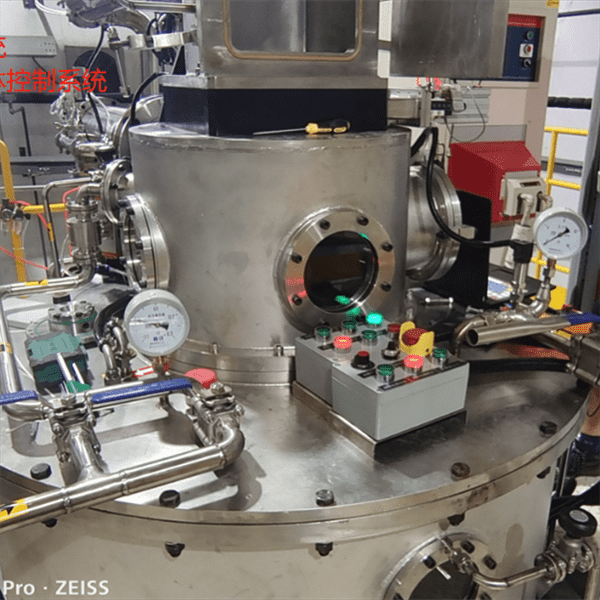

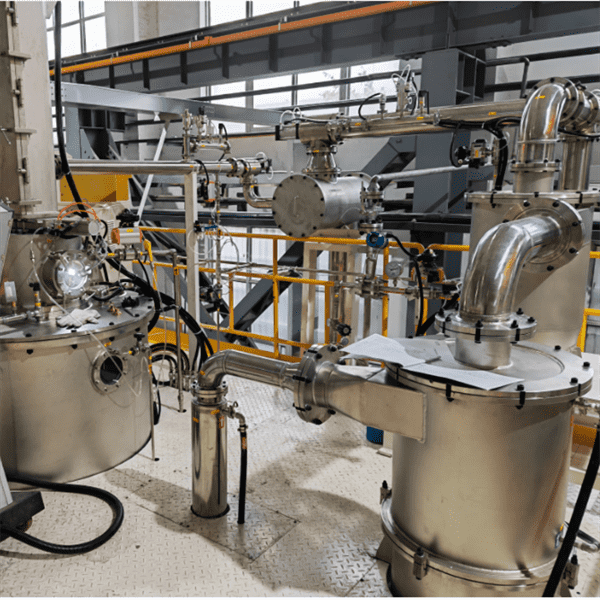

PREP Plasma Rotating Electrode Process Equipment

PREP equipment is mainly used to produce nickel-based superalloy powder, titanium alloy powder, stainless steel powder and refractory metal powder, etc. The powder produced is of high quality and is widely used in electron beam selective melting, laser melting deposition, spray coating, hot isostatic pressing, etc.

Application Area

Aerospace

Health

Tooling

Automobile

Machinery

New Energy

Electronics

Technical characteristics

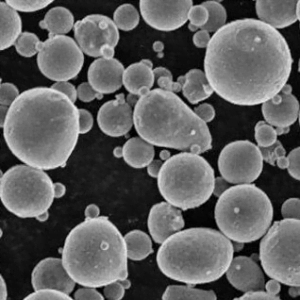

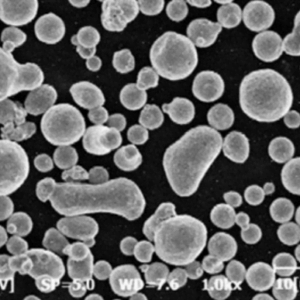

High-Quality Powder

PREP equipment ensures top-notch powder quality, characterized by a smooth, clean surface with minimal hollow or satellite particles and low gas inclusions, enhancing material integrity and performance.

Simple Process Parameter Control

With PREP equipment, controlling process parameters is straightforward. Its user-friendly interface allows for easy operation and automated production, simplifying workflows and reducing manual intervention.

Versatile Applicability

Highly adaptable, PREP equipment is well-suited for producing a diverse range of materials including titanium, nickel, cobalt, refractory metals, and alloys, meeting various manufacturing needs with ease.

Mature Process Technology

Built on mature process technology, PREP equipment offers reliability and efficiency. Its proven track record in research and batch production instills confidence in meeting industry demands efficiently.

Suitable Materials

-

Ti45Nb Powder for Additive Manufacturing

-

TiNb Alloy Powder

-

TiNbZrSn Alloy Powder

-

Ti6Al4V Powder Titanium Based Metal Powder for Additive Manufacturing

-

CPTi Powder

-

TC18 Powder : Unlocking the Power of Titanium Carbide

-

TC11 Powder : A Comprehensive Guide

-

TC4 ELI Powder

-

Best Ti-6Al-4V powder (TC4 Powder)for additive manufacturing

-

Titanium and aluminum TA7 powder

-

Pure Titanium Powder

-

Ti-6Al-4V Titanium Alloy Powder

Pulverizing Characteristics

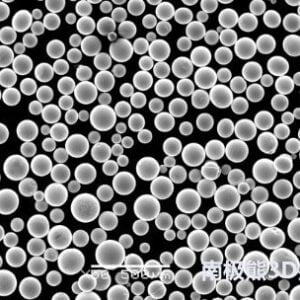

High Sphericity

PREP equipment consistently delivers powder with high sphericity, ensuring uniform particle shape and size distribution, which is crucial for various manufacturing processes.

Particle Size Range

With a versatile particle size range typically from 30 to 300 micrometers, PREP equipment offers flexibility to customize according to specific application requirements, accommodating various material needs.

Specific Example - Ti64 G5 Powder

For instance, in the case of Ti64 G5 powder, PREP equipment achieves a D50 particle size distribution ranging from 75 to 200 micrometers. This targeted size range is ideal for additive manufacturing and other applications where precise powder characteristics are essential.

Technical Parameter

| Induction Electrode Diameter | 50~80mm |

| Induction Electrode Length | ≤700mm |

| Bar Capacity | 60 |

| Rotaional Speed | 0~33000r/min |

| Overall Power | 200KW |

| Working Vacuum Degree | 6.67×10-3Pa |

| Ultimate Vacuum Degree | 6.67×10-1Pa |

| Pressure Rise Rate | ≤2Pa/h |

| Sphericity | ≥95% |

| Size(L×W×H) | 8m×7m×7.5m |

FAQ of PREP equipment

What is PREP equipment?

EIGA equipment is a specialized system used for the production of alloy metal powders through a process that involves electrode induction melting of the metal followed by gas atomization to form fine powder particles.

How does PREP equipment work?

PREP equipment operates by melting metal electrodes using a plasma arc, followed by atomization to produce fine powder particles. The rotating electrode design ensures uniform particle distribution and consistent quality.

What materials can be processed with PREP equipment?

PREP equipment is capable of processing a wide range of materials, including metals such as titanium, nickel, cobalt, and refractory metals, as well as their alloys, meeting various industrial needs.

What are the advantages of using PREP equipment?

Some advantages of PREP equipment include high sphericity of powder particles, precise control over particle size distribution, customization options for specific applications, and efficient production processes.

Is PREP equipment suitable for large-scale production?

Yes, PREP equipment is designed for both research and industrial-scale production, offering high throughput and scalability to meet the demands of various manufacturing applications.

Can PREP equipment produce powder with specific particle size distributions?

Yes, PREP equipment allows for precise control over particle size distributions, with the ability to customize parameters according to specific requirements, ensuring consistent quality and performance.

What quality assurance measures are in place for PREP equipment?

PREP equipment typically includes quality control measures such as particle size analysis, morphology examination, and chemical composition analysis to ensure the production of high-quality powders meeting industry standards.

Is training provided for operating PREP equipment?

Many suppliers of PREP equipment offer comprehensive training programs for operators, covering equipment operation, maintenance procedures, safety protocols, and troubleshooting techniques to ensure safe and efficient operation.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731