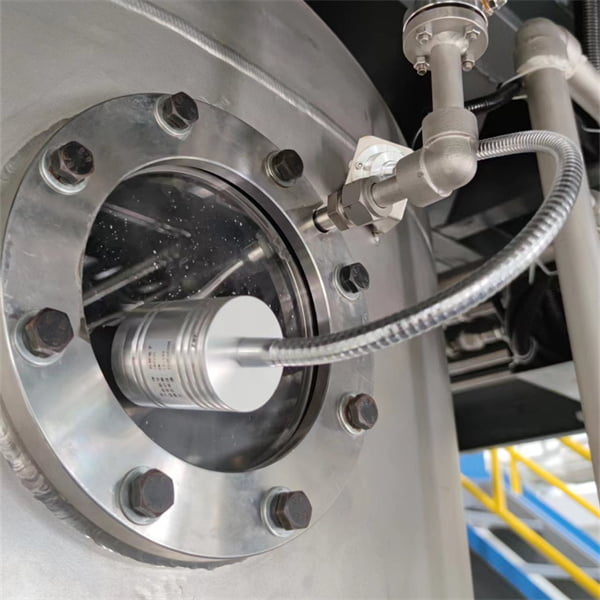

VIGA Vacuum Induction Inert Gas Atomization Equipment

VIGA equipment has a wide range of applications, mainly for the production of high-performance iron-based, nickel-based, cobalt-based, aluminium-based, copper-based and other advanced alloy powder materials. It is widely used in aerospace, health, tooling, automobile, machinery, electronics, new energy and other fields and also suitable for additive manufacturing (3D printing), melting deposition, laser cladding, thermal spraying, powder metallurgy, hot isostatic pressing and other advanced manufacturing processes.

Application Area

Aerospace

Health

Tooling

Automobile

Machinery

New Energy

Electronics

Process Characteristics

Versatility

We cater to a wide array of alloy metal powders, including stainless steel, die steel, superalloys, cobalt-chromium alloys, aluminum alloys, and more.

Diverse Materials

Our system accommodates various incoming materials, ranging from alloy ingredients to master alloys and return powder scrap, ensuring flexibility and resource efficiency.

Rapid Cooling

With an impressive cooling rate, our process achieves droplet cooling solidification rates of 103~106K/s, resulting in fine microcrystalline structures that enhance material properties.

High Purity

Operating under vacuum conditions, we refine alloys with minimal gas and impurity content, ensuring high purity and performance consistency.

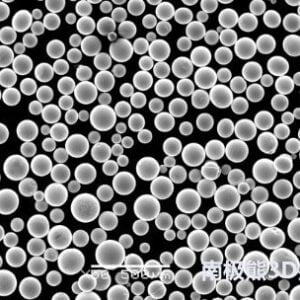

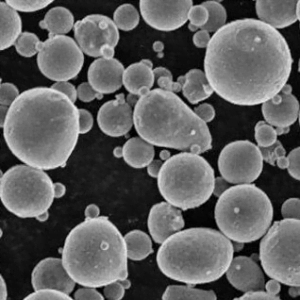

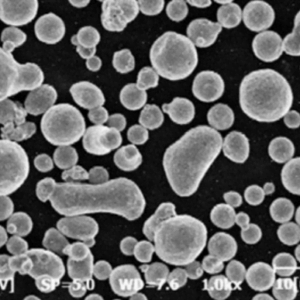

Superior Powder Quality

Our technology, whether employing tightly coupled or free aerosol nozzles, delivers powders with exceptional sphericity and controllable particle sizes, meeting the most stringent quality standards.

Simplicity and Efficiency

Designed for ease of operation and optimized for short preparation times, our process facilitates continuous mass production with minimal downtime, maximizing productivity and profitability.

Suitable Materials & Powders

-

Ti45Nb Powder for Additive Manufacturing

-

TiNb Alloy Powder

-

TiNbZrSn Alloy Powder

-

Ti6Al4V Powder Titanium Based Metal Powder for Additive Manufacturing

-

CPTi Powder

-

TC18 Powder : Unlocking the Power of Titanium Carbide

-

TC11 Powder : A Comprehensive Guide

-

TC4 ELI Powder

-

Best Ti-6Al-4V powder (TC4 Powder)for additive manufacturing

-

Titanium and aluminum TA7 powder

-

Pure Titanium Powder

-

Ti-6Al-4V Titanium Alloy Powder

Pulverizing Characteristics

Efficient Pulverization

VIGA equipment employs a vacuum induction system coupled with inert gas atomization, ensuring efficient pulverization of molten metal into fine powder particles.

Efficient Pulverization

VIGA equipment employs a vacuum induction system coupled with inert gas atomization, ensuring efficient pulverization of molten metal into fine powder particles.

Efficient Pulverization

VIGA equipment employs a vacuum induction system coupled with inert gas atomization, ensuring efficient pulverization of molten metal into fine powder particles.

Efficient Pulverization

VIGA equipment employs a vacuum induction system coupled with inert gas atomization, ensuring efficient pulverization of molten metal into fine powder particles.

Flexible Material Compatibility

VIGA equipment is versatile and compatible with a wide range of materials, including various alloy compositions and metals such as stainless steel, die steel, superalloys, cobalt-chromium alloys, and aluminum alloys.

Continuous Production

The VIGA process is designed for continuous production, offering high throughput and efficiency while minimizing downtime and production interruptions.

Technical Parameter

| Crucible Capacity | 10~500KG |

| Pouring Method |

Stopper Pouring for Small Furnace, Tundish Pouring for Large Furnace

|

| Max Temperature | ≤1750℃ |

| Temperature Measurement |

Mechanical and Dual Colorimetric Thermometry

|

| Holding Temperature | 1250℃ |

| Overall Power | 100~650KW |

| Working Vacuum Degree | 6.67×10-1Pa |

| Ultimate Vacuum Degree | 6.67×10-3Pa |

| Pressure Rise Rate | ≤2Pa/h |

| Inert Gas | N2/Ar |

| Atomizing Gas Pressure |

0~6MPa,Nozzle: 8MPa

|

| Atomizing Gas Flow |

10~30Nm3/min

|

| Size Distibution |

15~45μm, 15~53μm, 53~150μm

|

| Build Size |

Depending on the type of furnace

|

FAQ of VIGA equipment

What is VIGA equipment?

VIGA equipment is a specialized system used for the production of alloy metal powders through a process that involves vacuum induction melting of the metal followed by inert gas atomization to form fine powder particles.

How does VIGA equipment work?

VIGA equipment works by melting the desired metal in a vacuum chamber using induction heating. Once the metal reaches a molten state, inert gas is introduced to atomize the molten metal into fine droplets, which rapidly solidify into powder particles as they cool.

What materials can be processed with VIGA equipment?

VIGA equipment is versatile and can process a wide range of materials, including various alloy compositions and metals such as stainless steel, die steel, superalloys, cobalt-chromium alloys, and aluminum alloys.

What are the advantages of using VIGA equipment?

Some advantages of VIGA equipment include efficient pulverization, precise control over particle size distribution, high cooling rates leading to fine microcrystalline structures, low gas content in the powder, and the ability to achieve continuous production with customizable settings.

Is VIGA equipment suitable for mass production?

Yes, VIGA equipment is designed for continuous mass production of alloy metal powders. Its efficiency, throughput, and minimal downtime make it well-suited for industrial-scale production.

What quality assurance measures are in place for VIGA equipment?

VIGA equipment typically includes stringent quality control measures throughout the pulverization process to ensure the production of high-quality powder with consistent characteristics. This may include monitoring parameters such as particle size distribution, gas content, and powder purity.

Can VIGA equipment be customized for specific powder requirements?

Yes, VIGA equipment often allows for customization of various parameters and settings to meet specific powder requirements and production needs. This flexibility ensures that the produced powders meet the desired specifications and quality standards.

Is training provided for operating VIGA equipment?

Many suppliers of VIGA equipment offer training programs for operators to ensure safe and efficient operation of the equipment. These training programs typically cover equipment operation, maintenance procedures, safety protocols, and troubleshooting techniques.

Metal Powders for 3D Printing and Additive Manufacturing

COMPANY

PRODUCT

cONTACT INFO

- Qingdao City, Shandong, China

- [email protected]

- [email protected]

- +86 19116340731